Construction has always been an industry of quick decisions and constant adaptation. Yet despite technological advances, much of this decision-making still relies on fragmented communication and information scattered across disconnected systems.

Trimble recently visited 25 construction customers to better understand their workflows and technology needs, revealing a critical challenge: project teams have sophisticated technology solutions and vast amounts of data, but struggle to connect them meaningfully. The primary form of communication remains the phone, creating problematic disconnects on today's fast-paced projects.

Digital site management transforms this dynamic by addressing the fundamental question of why we need better information flow — to enable faster, more informed decision-making that keeps projects moving forward efficiently. Rather than simply documenting what happened, it empowers teams with the right information at the right time, enabling a shift from reactive problem-solving to proactive decision-making.

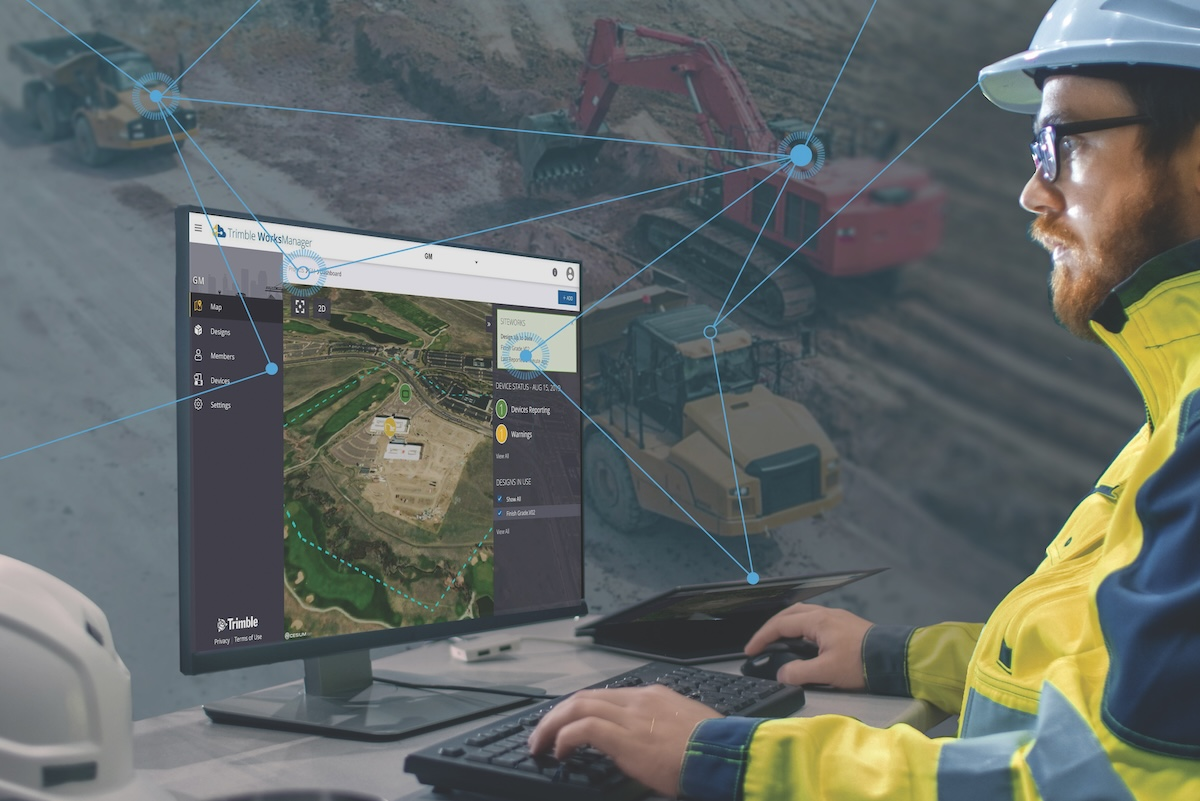

Digital site management builds on the familiar concept of connected construction, which focuses primarily on technical solutions and equipment connectivity. However, the approach goes deeper, emphasizing integrated workflows that capture not just technical data from surveys and models, but also rich contextual information from conversations and photographs that traditionally get lost in project folders.

At its core, this approach relies on common data environments that serve as centralized repositories for all project information. These centralized platforms are designed to work with existing multi-vendor technology investments, allowing companies to leverage their current mix of hardware and software while creating unified workflows that bridge previously disconnected systems.

| Your local Trimble Construction Division dealer |

|---|

| SITECH Allegheny |

| SITECH Northeast |

These platforms now include sophisticated functionality like geospatial data visualization tools that enable any team member to load models, interrogate data, and flag questions for both internal teams and external stakeholders. Digital solutions now allow foremen to request progress surveys through mobile apps, which automatically flow to surveyors and return completed results, eliminating traditional communication delays.

This integrated approach enables teams to anticipate challenges and adjust accordingly —whether rearranging crews before adverse weather hits, identifying underutilized equipment across job sites, or preventing utility conflicts before excavation begins.

To understand how these concepts translate to the real world, consider WW Clyde, a nearly century-old heavy civil contractor based in Utah. The company exemplifies how digital site management practices can transform project delivery, moving beyond data collection to actionable insights that drive better outcomes.

Lance Greer, Director of Construction Technology at WW Clyde, frames the challenge this way: "We can collect an insane amount of data, but the real value comes from making that data consumable and delivering it quickly enough so that it's still relevant for decision-making."

| Your local Trimble Construction Division dealer |

|---|

| SITECH Allegheny |

| SITECH Northeast |

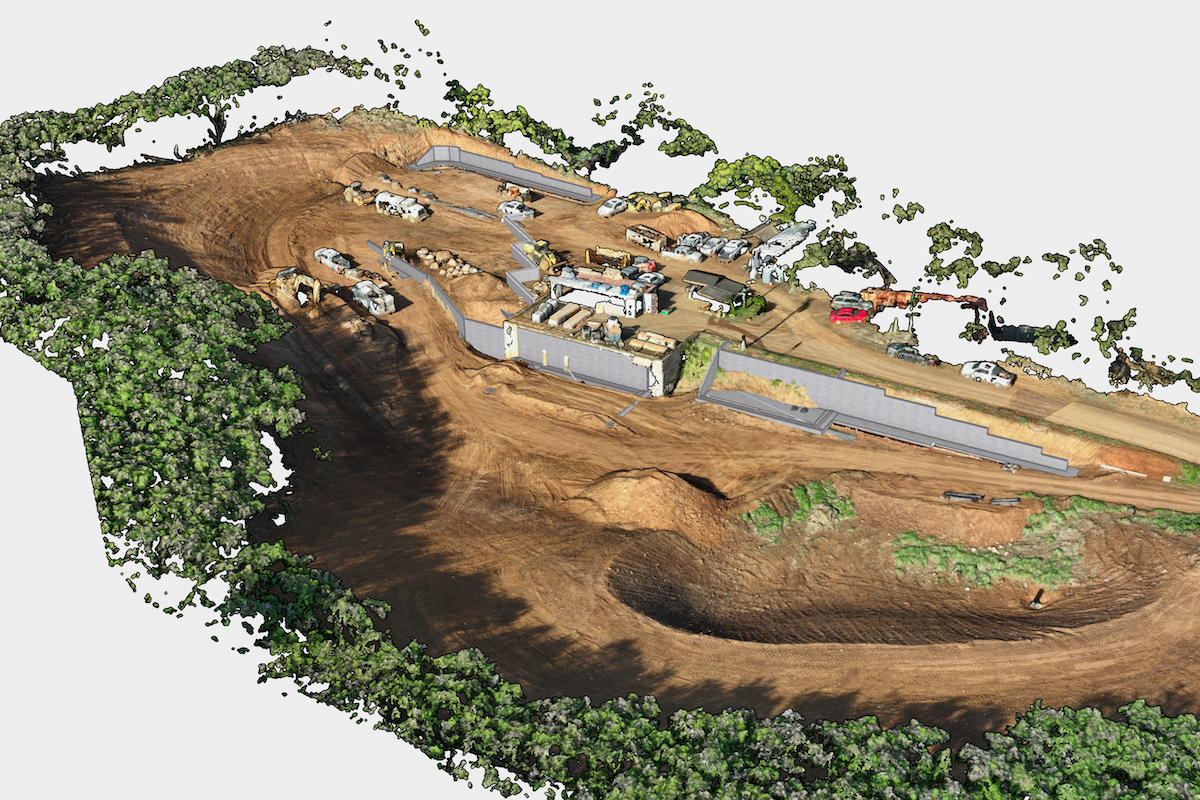

WW Clyde has built comprehensive digital workflows using Trimble Connect as its centralized platform to make project information instantly accessible to field teams on mobile devices. The company also leverages aerial drone surveys and augmented reality technology to visualize complex project data in the field. This approach proves particularly valuable on large projects like data centers, where they work with hundreds of miles of crossing utilities including fiber conduits, water lines, and electrical systems.

By uploading weekly progress photos and current as-built survey data to their centralized platform, field teams can see exactly what utilities are underground in their work area without waiting for survey support.

This visibility proves critical for both safety and efficiency. With accurate utility locations readily accessible on mobile devices, crews can avoid costly and dangerous utility strikes that traditionally result from outdated or incomplete drawings. The workflow has become a key component of WW Clyde's safety planning and risk mitigation efforts.

"We're able to deliver new information to the field regularly, which empowers teams to make real-time decisions rather than reactive ones," said Cole Palmer, WW Clyde's CAD Manager.

| Your local Trimble Construction Division dealer |

|---|

| SITECH Allegheny |

| SITECH Northeast |

On BIM-coordinated projects, WW Clyde can identify potential clashes well in advance of installation, virtually eliminating field rework. Steve Okelberry, a Senior CAD Technician at the company, noted the operational impact: "This workflow often eliminates the need for us to send a survey technician out to support work. It puts the data and the decision-making directly into field teams' hands."

The speed advantage becomes particularly dramatic during change orders and design modifications. During a recent project in Hawaii, WW Clyde used drone data to facilitate design changes that were reviewed by stakeholders in Alaska, approved, then quickly implemented in the field.

"We took what could be at least a two- to four-week process and reduced it to one hour," Greer said. "When you step back and look at it, we saved three weeks and several hundred thousand dollars in schedule delays and change orders."

These improvements extend beyond cost savings to relationship building. "We're providing field teams with the tools they need, teaching them to fish rather than giving them the fish,” Okelberry said. “This builds trust where they can call us when needed, but also feel confident making decisions independently."

| Your local Trimble Construction Division dealer |

|---|

| SITECH Allegheny |

| SITECH Northeast |

This trust-building extends to owner relationships. When project data is centralized and accessible, it creates transparency that reduces costly disputes and streamlines project delivery.

As artificial intelligence capabilities mature, the construction industry stands poised for even more significant advances. AI algorithms are already flagging potential clashes in point clouds, identifying specific features in massive datasets, and supporting improved estimating and risk assessment.

Future applications may include superintendents using AI prompts to get recommendations during weather events, automatically identifying available equipment across multiple job sites, or analyzing historical data to suggest optimal work sequences. Safety applications are equally promising, with the potential for real-time proximity alerts when equipment approaches buried utilities, automated incident reporting that captures contextual project data, and predictive analytics that identify high-risk scenarios before they occur.

However, the foundation for these advanced capabilities lies in bringing historically disparate data together and establishing connected workflows today. The most successful companies view digital site management not as a single technology solution, but as an integrated ecosystem where tools share data seamlessly.

| Your local Trimble Construction Division dealer |

|---|

| SITECH Allegheny |

| SITECH Northeast |

The promise of digital site management follows a clear progression that moves from descriptive analytics helping teams understand what happened to predictive capabilities that forecast future events, and ultimately to prescriptive management where systems can suggest changes to work plans based on weather conditions, resource availability, and project constraints.

For construction companies ready to embrace digital site management, success begins with clear objectives that address underlying challenges — reducing rework, improving communication, and empowering field teams with better information.

Companies that establish centralized data repositories, implement mobile-friendly interfaces, and create processes that capture and share critical decision-making information will find themselves with significant competitive advantages as project scope and scale increase, regulatory requirements become more demanding, and timelines compress.

The key is starting with integrated thinking rather than isolated technology purchases. Success requires investment in both technology and training, along with breaking down information silos that traditionally separated office and field operations.

| Your local Trimble Construction Division dealer |

|---|

| SITECH Allegheny |

| SITECH Northeast |

WW Clyde’s results demonstrate the potential: projects that once required weeks of back-and-forth approvals now complete design changes in hours, and teams thousands of miles apart collaborate as if they're standing on the same job site. This transformation isn't future technology — it's happening today on construction sites across the industry, creating new standards for efficiency, collaboration, and project delivery.