The Orange County Transportation Authority (OCTA) is heading up a complex and intertwined set of projects on and along California SR 55, starting at the I-405 intersection in Irvine and then running 4.3 miles north to the junction with I-5.

This section of SR 55, within the cities of Santa Ana, Tustin, and Irvine, California, is among the most heavily trafficked highways in the nation. According to OCTA, more than 260,000 vehicles use this stretch of highway every day. That number is expected to grow to nearly 275,000 vehicles by 2040.

The $506 million project — about $117 million per mile — includes:

- Adding one regular lane and one carpool lane in each direction, as well as merge lanes between several interchanges and reconfiguring on- and off-ramps.

- Relocating or resizing adjacent neighborhood streets.

- Improving four freeway bridges at MacArthur Boulevard, Dyer Road, Edinger Avenue, and a railroad crossing.

- Constructing new drainage systems, including the 3,139-foot-long Lane Channel, which runs parallel to southbound SR 55 and provides regional flood control. This channel reconstruction was necessary to make way for the expanded freeway.

The SR 55 Improvement Project has a long history. Construction began in August 2022 and is expected to be completed in 2027. However, environmental work started in 2014 and project design in 2017. The California Department of Transportation’s (Caltrans) review started in 2021, and the project was awarded to Security Paving in 2022.

| Your local Gomaco dealer |

|---|

| Terry Equipment |

On its website, OCTA describes the SR 55 work as a “multi-asset project,” since — in addition to its highway infrastructure — the right of way contains equipment and infrastructure for multiple utility pathways, from electric and gas to water and communications.

OCTA officials coordinated the complexities inherent in working on these varying assets, working, more or less, all at the same time.

OCTA Spokesman Eric Carpenter, in consultation with the lead engineers on the project, explained that work progressed within three broad stages, with multiple phases within each stage. For example, the reconstruction of six ramps adjacent to the MacArthur Boulevard intersection was divided into phases in order to maintain traffic, since all the ramps could not be closed simultaneously.

Construction started along the outside portion of the roadway. This included bridge widenings and building retaining walls. When the walls were completed, drainage work got underway. Next came lighting and installing communication conduits. Finally, paving.

| Your local Trimble Construction Division dealer |

|---|

| SITECH Southwest |

| SITECH West |

“This approach in staging and coordination prioritized work site safety,” Carpenter said. “Plus, it minimizes traffic disruptions for drivers and maximizes efficiency because it allows us to schedule, when possible, overlapping tasks while still adhering to environmental requirements.”

The contractor is required to adhere to stormwater pollution prevention plans to protect water quality from construction activities. Staging allows drainage systems to keep functioning as work progresses.

Carpenter especially noted the reconstruction at four major freeway interchanges: MacArthur Boulevard, Dyer Road, Edinger Avenue, and McFadden Avenue. He said construction at these locations could occur at the same time because of the construction team’s detailed scheduling and use of scheduling software tools, such as Primavera Scheduling Software, a tool that helps model the project and plan out resources.

Drainage has been a persistent problem and correcting it has been a top priority. OCTA’s lead engineer said that water challenges result from a combination of seasonal rainfall, localized runoff, and groundwater seepage. During their work, construction teams used temporary pumps and diversion systems to prevent ponding and control erosion, allowing roadbed compaction to proceed on schedule. For the future, an upgraded storm drain system will be able to handle higher flows.

| Your local Gomaco dealer |

|---|

| Terry Equipment |

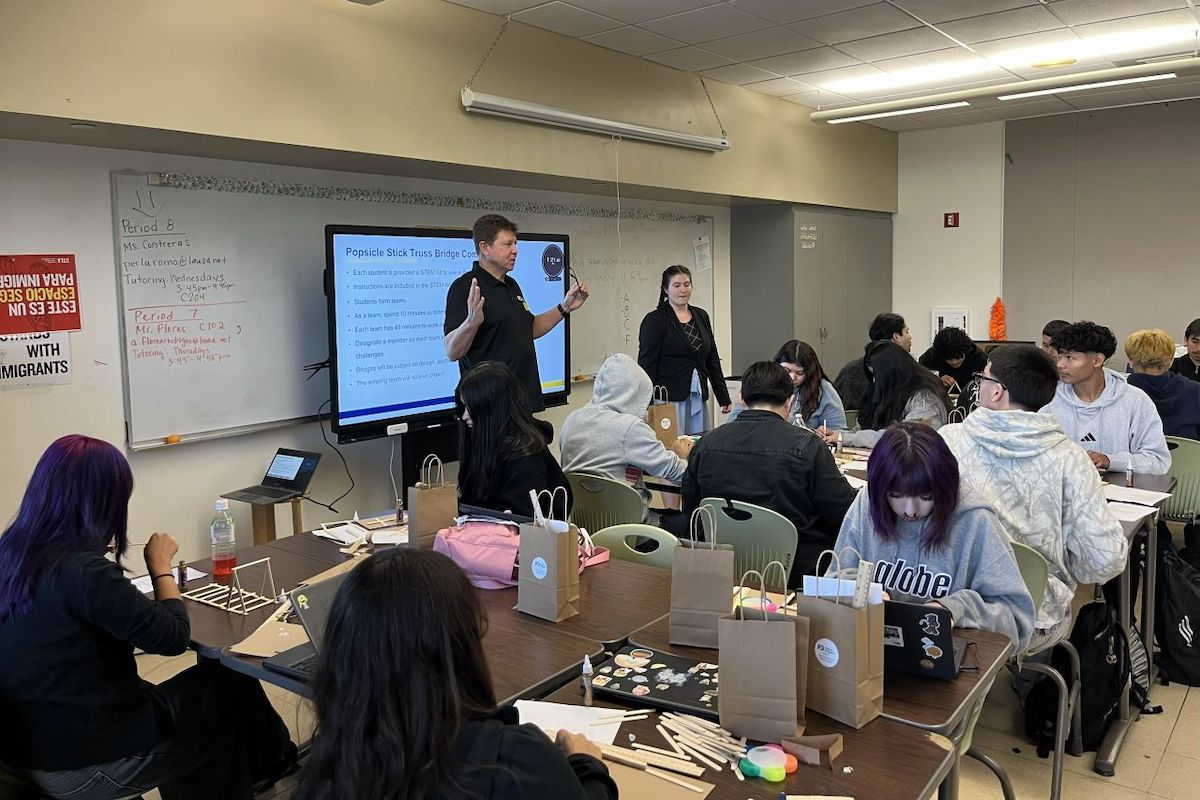

Because of intense traffic volumes, project managers confronted a uniquely hazardous work site. Caltrans oversees work site safety, with support from OCTA, and the construction team implemented enhanced traffic control plans as established by Caltrans.

These include K-rail barriers, dynamic message signs, and California Highway Patrol enforcement to discourage speeding through the construction areas. K-rail barriers are the pre-cast concrete, steel-reinforced walls used to separate lanes of traffic and provide protection. They are called Jersey barriers in much of the U.S. The project requires 18 retaining walls. Six are under construction, and 12 are complete.

Carpenter said some unique traffic-related challenges included maintaining peak-hour lane capacity. Lane closures were limited to nights and weekends. He added that there has been a “noticeable reduction in traffic during construction phases.” Drivers are encouraged to use alternate routes or use mass transit. OCTA’s communication team provides regular updates to help travelers, including working with the mapping teams at Waze and Google Maps.

A project at this scale bumps into the local street grid pretty quickly, and in metropolitan Southern California, there is not much room to spare.

| Your local Gomaco dealer |

|---|

| Terry Equipment |

Carpenter explained that the right of way requirements vary along the SR 55 corridor. However, he said the freeway widening “generally extends the footprint 20 to 30 feet in each direction to accommodate added lanes, retaining walls, and K-rail installation.”

Impacts on local streets have varied. For example, the overall roadway widths for Cowan, Pullman, and Ritchey streets will be reduced, but those roads will still maintain standard lane widths for traffic. As important connectors within the local street grid, the roads run close to and roughly parallel to SR 55, link the areas around the footprints of the four project interchanges, and offer a non-highway route.

Carpenter said that “significant reconstruction was required for about 2 miles of local streets,” including improvements to intersections at Dyer Road and Edinger Avenue to improve merge and diverge points. This work involved grading, paving, signal upgrades, and adding auxiliary lanes to handle diverted traffic.

“Overall, we've reconstructed approximately 1.5 miles of frontage roads to align with the widened freeway,” Carpenter said. For comparison, the total length of freeway work is just over 4 miles.

| Your local Gomaco dealer |

|---|

| Terry Equipment |

Security Paving has largely used standard industry construction equipment on the SR 55 Improvement Project. The company set up a recycling plant to take delivery of the asphalt and concrete removed from the project site. This material goes to a crush yard where the asphalt and concrete are repurposed for use as aggregate base material, eliminating the need to transport old material to landfills and making it easier to return the crushed base to be incorporated back into the roadway section.

Regarding new technology, the design engineer HDR has included the use of expanded polystyrene geofoam blocks (EPS) for lightweight backfill of two large retaining walls. EPS may be used where settlement is a concern. EPS blocks are lightweight with a density of 4 pounds per cubic foot, and this backfill method will prevent settlement and avoid “uplifting” effects on neighboring properties including housing structures, streets, and sidewalks or parking lots.

OCTA took an active role in the relocation of nearly all utilities within the project footprint. Work included utility equipment and infrastructure for telecommunications and water/sewer pipes. There were several overhead transmission and distribution lines operated by Southern California Edison that were relocated between Dyer Road and Edinger Avenue to accommodate the widening. The project impacted providers such as Southern California Edison, AT&T, and local water districts.

“Our approach to timing and scheduling involved early utility coordination meetings during the design phase, where we designated specific timeframes for relocations,” Carpenter said.

| Your local Gomaco dealer |

|---|

| Terry Equipment |

Utility companies could not always work simultaneously due to their own crews and permits. Individual schedules were managed through a master schedule.

“This incorporated what we called the contractor’s ‘critical path schedule’ to ensure the relocation would be done ahead of the planned work to avoid impacts to the overall project schedule,” Carpenter added.

The bridge construction posed some challenges, one of which was staging demolition of the existing bridge overhangs (the section of the bridge deck that cantilevers, or projects, outward from the last main support beam) followed by reconstruction over live traffic. This was needed not just once, but at all of the new bridge sites.

“This required careful planning of nighttime closures,” Carpenter said, as well as “detailed safety reviews to protect motorists and workers and close coordination with Southern California Railroad Authority [SCRRA/Metrolink].” Overhang demolition was typically scheduled between 9 p.m. and 5 a.m.

| Your local Gomaco dealer |

|---|

| Terry Equipment |

Another challenge was building the footing for the bridges in locations near area hotels. Disruptive activities, like pile driving, were rescheduled. Instead of occurring at night, as originally planned, that work was shifted to the daytime. The change required the contractor, Security Paving, to seek additional work areas. Fortunately, new sites were found and pile driving operations progressed on schedule.

- Owners: Orange County Transportation Authority; California Department of Transportation

- Project Sponsor: Orange County Transportation Authority, Orange County, California

- General Contractor: Security Paving, Inc., Westlake Village, California

- Construction Management: AECOM, Dallas, Texas

- Designer/Engineer: HDR, Inc., Omaha, Nebraska