The construction industry operates on precision, timing, and accountability. Between managing equipment across multiple job sites and ensuring compliance with safety and maintenance regulations, even the smallest inefficiencies can cost thousands of dollars and derail project timelines. Asset tracking tools allow contractors to streamline operations, work smarter, reduce downtime, and safeguard profitability.

Paper logs, spreadsheets, and outdated databases are unable to keep pace with the mobility and rapid advancements of modern construction. This is where asset management platforms make a huge impact, enabling managers to track various assets and equipment, build out existing workflows, and grant customizable user permissions.

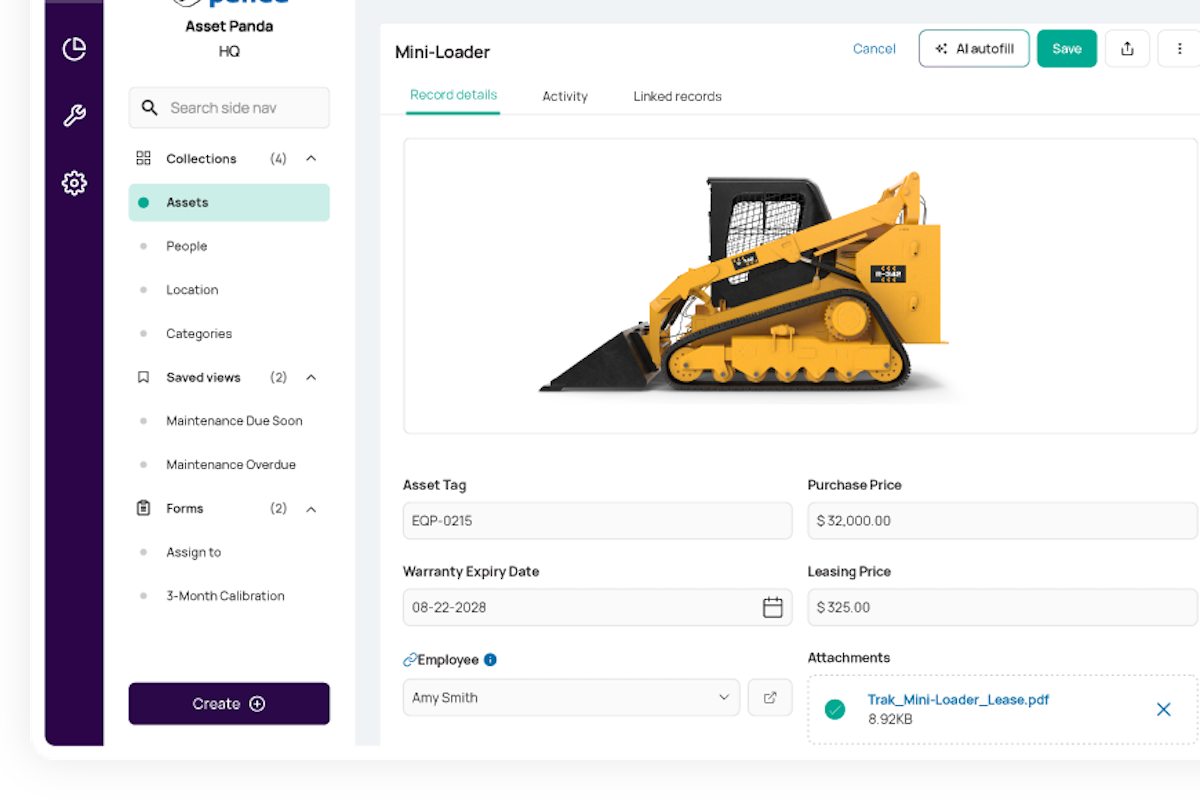

Asset management software also allows workers to track or check out tools, vehicles, and heavy equipment in real time — whether they’re in the office, onsite, or miles from the nearest network signal. Armed with a mobile app, teams can scan barcodes and update asset records from a smartphone or tablet. Even in remote areas with limited or no connectivity — standard on most construction sites — an offline mode can ensure users capture critical data. Once connectivity is restored, all updates can sync to preserve data integrity and prevent costly errors or duplication.

With complete transparency into tasks and resources, managers can optimize scheduling and asset tracking to boost productivity.

Every piece of equipment, regardless of size, has a lifecycle — from acquisition and operation to maintenance and eventual disposal. When an asset quits working, it can lead to project delays, overtime costs, and penalties for missed deadlines. That’s why real-time access to repair history and warranty information is critical.

| Your local Trimble Construction Division dealer |

|---|

| SITECH Allegheny |

| SITECH Northeast |

Asset management software helps managers stay ahead of maintenance schedules, monitor usage patterns, and set automated reminders for inspections or service intervals. These proactive measures minimize unplanned downtime, improve safety, and extend the life of high-value machinery. Capturing data such as run hours, maintenance history, and warranty information also drives data-driven decisions about when to repair, replace, or retire assets.

Many systems now include AI-powered features designed to improve operational efficiency and reduce reliance on manual tracking. For instance, say a construction office needs to import a spreadsheet of laptops with numerous data points for each device. AI column mapping helps quickly pair spreadsheet headings to the right fields so employees don’t have to manually map 10, 20, or 30 fields. That saves time and ensures accuracy.

While construction companies may have similar needs, no two companies are exactly the same — yet many firms lack the support to create custom fields for items such as equipment type, job location, safety certifications, or depreciation values. To address this challenge, no-code platforms enable easy configuration to match exact workflows without the need for developers or IT support.

For companies managing multiple sites or departments, a multi-account management feature provides centralized oversight and maintains security across different teams. Each department or project can maintain its own records, yet leadership retains visibility into the whole operational picture.

| Your local Trimble Construction Division dealer |

|---|

| SITECH Allegheny |

| SITECH Northeast |

AI adds another layer of efficiency. Users can create customized intelligent automations triggered by specific conditional fields, helping to streamline tasks and stay on top of routine workflows.

The return on investment for asset tracking software goes beyond the technology itself — it helps foster a culture of accountability and efficiency across the organization. When field teams have tools that simplify their jobs and remove guesswork, they’re more likely to follow best practices consistently.

Whether tracking which employee last used a piece of machinery or ensuring compliance with maintenance schedules, a standardized process supported by audit trails is essential. With digitized records and centralized data, construction firms gain valuable insights to facilitate capital planning. Leadership can identify underutilized equipment, allocate resources more effectively, and plan purchases with confidence. Over time, these improvements compound by reducing operational waste, enhancing compliance, and improving margins on every project.

Creating custom workflows and user permissions enables supervisors to define access levels, ensuring that every check-out, transfer, or inspection is documented correctly. A clear audit trail then makes it easier to trace accountability and verify compliance with safety and equipment policies. Not only is reporting simplified, but internal controls are strengthened and the risk of loss, theft, or mismanagement is reduced.

| Your local Trimble Construction Division dealer |

|---|

| SITECH Allegheny |

| SITECH Northeast |

Manual asset management is no longer sustainable in today’s construction industry. Mobile-adapted, intelligent, customizable solutions that fit specific workflows provide the visibility and control needed to keep fast-paced projects on schedule and within budget.

Rex Kurzius is CEO and Founder of Asset Panda.