Most schedule updates I see follow the same script. Someone opens the file the night before a meeting, nudges a few dates, tweaks percent complete on a handful of activities, saves, and walks into the room with a “fresh” schedule. On paper, the job is still tracking. In reality, almost nothing important has changed.

What almost never happens first is the one thing that matters most: a quick check of whether the bones of the plan are still sound.

After two decades inside schedules on distressed projects and claims, I’ve noticed a consistent pattern: Teams that deliver on time tend to share a small habit — a quick structural check before every update and the discipline to act on what it uncovers.

We all know the industry’s track record. A recent roundup of project statistics noted that only about 35 percent of projects today are completed successfully in terms of scope, time, and budget. Analyses of project management data have tied a big share of failures to poor control of milestones.

We’re not short on updates; we’re short on reliable models behind those updates.

| Your local Komatsu America Corp dealer |

|---|

| Road Machinery and Supplies Company |

A critical path method schedule is supposed to be that model. When the logic is coherent and the plan is maintained with discipline, the schedule behaves like a map of cause and effect: If I change this activity or this constraint, I can see how risk flows through the network. But when the structure quietly degrades with ties dropped, activities stretched into vague “buckets,” and finish dates pinned with hard constraints, the model stops being a forecast and becomes wishful thinking rendered as a Gantt chart.

That’s where an update gate comes in.

When I talk about a “quality gate,” I don’t mean a massive checklist. I mean a short, repeatable scan you run before anyone touches status. On a real job, it looks like this: The scheduler opens the file for the monthly update, and before asking superintendents for progress or sliding any dates, they answer a few structural questions.

First, they look for orphaned activities — tasks with no predecessor, no successor, or both. These are the little land mines that quietly break the chain of cause and effect. An inspection that can start anytime or a piece of site work with no clear successor might seem harmless, but a handful of these can completely distort the apparent critical path. If the work is real, it needs to sit somewhere in the flow; if it isn’t real, it needs to come out.

| Your local Link Belt dealer |

|---|

| Hayden-Murphy Equipment Co |

Next, they scan for overlong “bucket” activities. Anything that spans more than four to six weeks without a clear internal handoff is suspect. “Interior MEP rough-in – Levels 3–10” sitting there as a 70-day bar is a classic example. No one really knows what “40 percent complete” really means on that activity. The project might have finished Levels 3–4 completely and never touched Level 7, but the reporting will show a comfortable, averaged-out number that hides both risk and opportunity.

Then they take a hard look at constraints and manual dates. A few hard dates are fine when they represent genuine external commitments. But when you see finish dates pinned all over the place or a “must finish on” constraint that’s been driving negative float for three months, you’re no longer looking at an honest picture of risk. You’re looking at a schedule that has been forced to tell a politically convenient story.

Finally, they check for unexplained negative float. Short bursts of negative float can be useful; they’re a flashing light that says, “We made a promise the model doesn’t currently support.” But persistent negative float that gets carried from update to update is a sign that the team is sliding dates without really solving the problem. The gate forces a conversation: resequence, re-resource, or reset the commitment. Doing nothing is not an option.

Run through that sequence once and you’ve already filtered out the worst structural distortions. Now, and only now, does it make sense to record actuals and move dates.

| Your local Volvo Construction Equipment dealer |

|---|

| Nuss Truck & Equipment |

Two changes make this habit much more powerful in practice:

- Breaking down buckets

- Standardizing how you credit progress

Let’s go back to that 70-day rough-in activity. On the first pass, you replace it with a short chain of activities that reflects how the work really flows, maybe by level, zone, or system. Each one is short enough that a superintendent can stand in the space and say, “We’re done here,” or “We still have three risers to pull.”

Then you define simple rules of credit that everyone understands for percent complete. For example, you might agree that rough-in on a level is zero percent until layout is complete, 25 percent when hangers and supports are installed, 50 percent when main runs are in, 75 percent when branches are pulled, and 100 percent when it’s ready for inspection. The exact numbers will vary by trade and project, but the principle is the same: Avoid fuzzy, seat-of-the-pants percentages.

Once those rules are in place, the five-minute gate gets even faster. If a long, vague activity sneaks back into the plan, it stands out. If an update shows 80 percent complete on a task that hasn’t hit the agreed-upon handoff, that stands out, too. You’re no longer debating feelings about progress; you’re checking the schedule against a shared definition of “done.”

| Your local Trimble Construction Division dealer |

|---|

| SITECH Dakotas c/o Butler Machinery |

| Fabick CAT/WI |

The biggest question I get from contractors is, “Will the field buy into this, or will they see it as extra paperwork?”

My experience is that superintendents and foremen are far more willing to support a gate like this than many people assume — if you frame it properly. The pitch is simple: It’s about avoiding end-loaded, panic-driven heroics.

Most field leaders have lived through the same painful pattern: Early updates are rosy, the schedule shows green bars across the board, and then, somewhere around the last third of the job, everything compresses. Windows melt, overtime becomes standard, and people start talking more about claims strategy than delivery.

When they see that a five-minute structural check can catch trouble in the model months earlier — before it turns into weekend shifts and rework — they’re usually on board. The gate protects them from having to fix problems that could have been handled when they were still abstract.

| Your local Gomaco dealer |

|---|

| Hayden-Murphy Equipment Co |

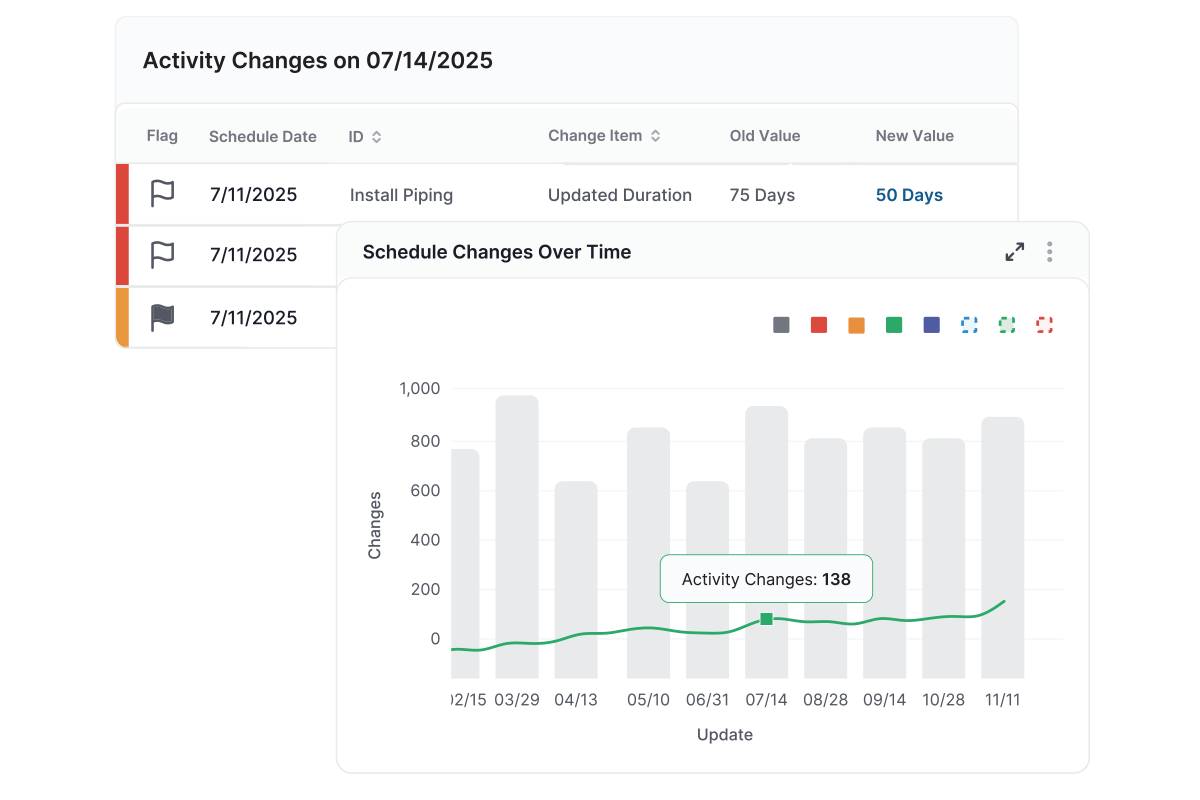

The other reason it lands well is that it’s visible and finite. You can show a superintendent, “Last month we had 40 activities with missing ties and 10 overlong buckets. This month we’re down to five and two.” You’re putting discipline in service of predictability, not asking them to become schedulers.

The payoff from this habit isn’t dramatic. That’s the point. You don’t get a big, cinematic moment where everything turns around. What you get is a series of quieter outcomes — fewer surprise slips, fewer “we have to resequence the whole job” meetings, fewer late-stage compressions that everyone knows are unsafe, but no one feels empowered to challenge.

Over time, you also see something harder to measure but easy to feel: trust. When the schedule is consistently run through a structural gate before each update, people around the table stop arguing about whether to believe it. They know the logic has been checked, the buckets have been broken down, and the constraints have been examined. That frees them to have conversations that actually matter: where to focus, how to de-risk, what to change in the field.

We’re not going to solve construction’s predictability problem overnight. But we don’t have to wait for a perfect world, either. If you’re running projects today, you can start with this: Before your next update, ask your team to spend five minutes checking the bones of the plan. Fix what you find. Then move the dates.

| Your local Komatsu America Corp dealer |

|---|

| Road Machinery and Supplies Company |

Do that every month, on every job, and you’ll be surprised how much less you’re surprised.

Michael Pink is CEO and Founder of SmartPM. Images courtesy of SmartPM.