Construction risk is too often treated like a paperwork ritual, captured in registers, debated at monthly meetings, and diagnosed after the fact. Meanwhile, the earliest and most actionable risk signals are already beating inside the schedule.

The critical path is the project’s heartbeat. When near-critical float erodes, constraints stack up, logic goes brittle, or crews drift out of sequence, those issues are not data quirks. They’re early warnings of missed milestones, congested job sites, safety exposure, and budget creep. On most jobs, treat “near-critical” as activities with only a small amount of float — because they can become the path with a single slip.

A logic-linked schedule remains a project’s best forward-looking model. The U.S. Government Accountability Office’s (GAO) schedule guide lays out 10 practices capturing all work, logical ties, calibrated durations and calendars, and transparent updates that turn a schedule from a picture of hope into an evidence-based forecast. That guidance still underpins how owners and auditors judge credibility today.

In practical terms for contractors, that means:

- Capture all work

- Give every activity real predecessors and successors

- Base durations on quantities, crew rates, and appropriate calendars

- Connect detailed tasks to milestones so roll-ups and work breakdown structure trace cleanly

- Verify a traceable critical path

- Keep float values believable

- Think through “what-if” schedule risks

- Update with actual starts/finishes and logic changes rather than sliding dates

- Preserve an approved baseline for variance analysis

Quality has to come before dates. Quick integrity diagnostics, checking for missing logic, negative float, excessive lags, and long open-ended activities tell you whether the plan’s “bones” can carry decisions.

| Your local Deere & Co dealer |

|---|

| AIS Construction Equipment |

| AIS Construction Equipment |

The Defense Contract Management Agency’s (DCMA) 14-point criteria provide a fast, widely taught yardstick for that basic health check. Before debating finish dates, run a compact scan:

- Remove open ends and missing logic

- Avoid negative lags and keep long lags to genuine cases

- Prioritize finish-to-start over exotic relationships

- Minimize hard date constraints that hide float

- Resolve any negative float at the source

- Break very long tasks into controllable segments

- Align calendars and status dates with reality

- Confirm that a slip on the critical path actually moves the project finish

The real advantage comes from what you track week to week.

Near-Critical Volatility

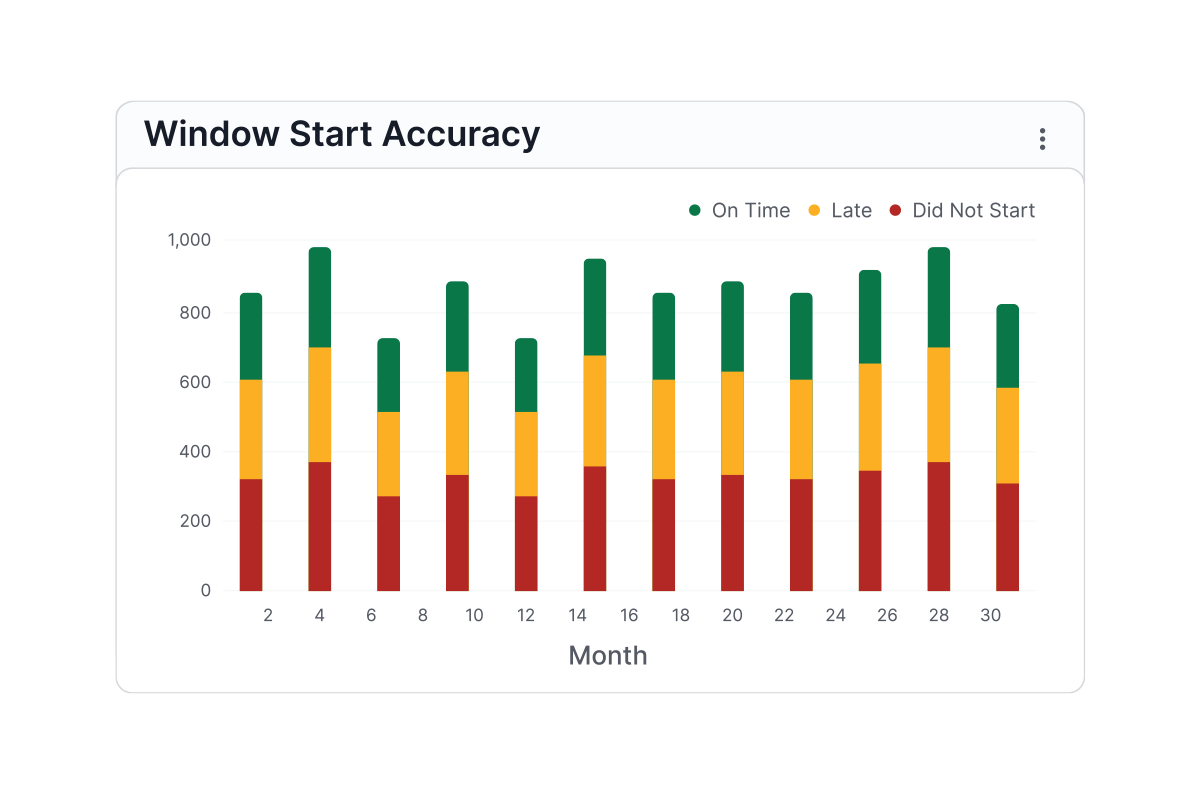

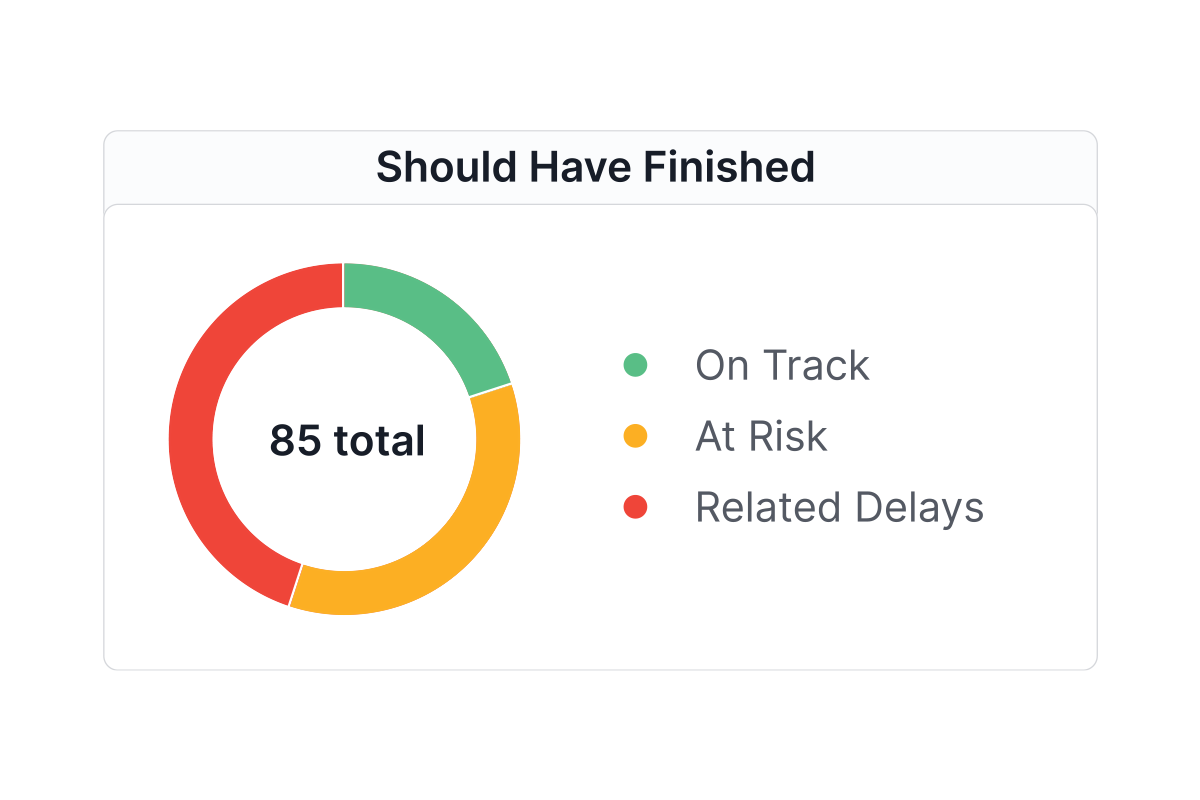

Activities with small total float can become tomorrow’s longest path with a single slip. Modern planning systems explicitly support multiple float path analysis so teams can track that near-path set as it evolves, providing an early view of where sequence conflicts will form.

Out-of-Sequence Work

When the field builds out of order, flow breaks and interference rises. Recent peer-reviewed work quantified how out-of-sequence (OOS) execution degrades schedule and cost performance across dozens of projects. Earlier studies documented its causes and warning signs. Treat OOS like smoke near the path: find it, ask why, and remove the driver before it spreads.

| Your local Trimble Construction Division dealer |

|---|

| SITECH Michigan |

| SITECH Michigan |

Constraint Pressure Near the Path

When unresolved constraints cluster near the path or its neighbors, risk accelerates. Lean construction’s make-ready discipline exists to defuse exactly this problem, and recent research from Dodge and the Lean Construction Institute again tied stronger lean intensity to measurably better outcomes.

Brittle Logic

Missing predecessors/successors, hard constraints, and heavy lags hide fragility. Clean ties sharpen the risk picture; messy ties make every what-if a guess. A light GAO/DCMA-style cleanup before you debate dates is time well spent.

A weekly rhythm of attention to the schedule goes a long way in preventing problems.

Keep it simple and narrative. Start by running a quick integrity pass. Fix obvious gaps, then compare this week’s longest and near-longest paths to last week’s and explain why they moved. Do this in the native schedule file: update actual starts/finishes and remaining durations, recalculate, and run your tool’s integrity and out-of-sequence reports so float and logic refresh before the meeting.

| Your local Deere & Co dealer |

|---|

| AIS Construction Equipment |

| AIS Construction Equipment |

Keep a live constraint log mapped to each item’s activities unblocks, and put a colored edge around anything touching the near-critical band. If the finish forecast has drifted, explain the variance at the activity/logic level, not with generic labels. Capture a brief variance note naming the specific activities and ties that drove the change, then model one realistic what-if (such as splitting a task, adding a shift, or resequencing a hand-off) and record the effect before you meet.

Package the output on a single page that includes a brief “what changed and why,” the path/near-path deltas, a constraint snapshot by distance to path, and a change log with modeled impacts. That cadence turns the schedule from a rear-view report into a forward-focused decision tool. Distribute that page to superintendents, project managers, and trade partners ahead of the weekly huddle so actions such as resequencing, adding crew, or releasing holds are decided on the spot.

Research has synthesized the link between production/schedule pressure and degraded safety performance — exactly the conditions created by unstable paths and OOS work. Treat schedule stability as a safety control. Fewer shocks to the plan mean fewer risky improvisations in the field.

Two things have changed since the industry’s “just work harder” era. First, modern planning tools make near-critical behavior visible in minutes, not days, so the right conversation can happen before crews collide. Second, the research base is broader and newer, from empirical OOS impact studies to lean predictors that correlate with schedule accomplishment during execution. Together they point to the same conclusion: The sooner you see instability in the schedule, the less you’ll feel it in the field.

| Your local Deere & Co dealer |

|---|

| AIS Construction Equipment |

| AIS Construction Equipment |

Risk is visible earlier than most teams act on it. When you make the schedule the center of weekly decision-making and keep the focus on quality and near-path stability, projects get quieter in the right ways — more predictable, more collaborative, and safer.

Michael Pink is CEO and Founder of SmartPM. Images courtesy of SmartPM.