The massive $3 billion, 10-year New Lock at the Soo program in Sault Ste. Marie, Michigan, nears the halfway mark with one of the final contracts underway to remove an aging, no-longer-used lock and replace it with a modern, deeper, and wider lock — the second at the facility.

“The Soo Lock facility is a critical bottleneck point between Lake Superior and the lower great lakes for the shipping industry,” said Rachel Miller, New Lock at the Soo Supervisory Civil Engineer and Contracting Officer’s Representative for the U.S. Army Corps of Engineers (USACE), Detroit District. Miller described the lock as a water elevator.

Lake Superior, the westernmost Great Lake, is 23 feet higher than the other lakes. Canada sits just north of the lock and the St. Mary’s River. An international bridge passes above the project. Eighty-eight percent of high-strength U.S. steel requires iron ore that passes through the Soo Lock, which was placed on the National Register of Historic Places. About 7,000 boats travel through the locks each year, carrying up to 75 million tons of cargo. The USACE reports a six-month Poe Lock closure would temporarily reduce the U.S. gross domestic product by $1.1 trillion, resulting in the loss of 11 million jobs.

Two locks currently operate at the facility, which opened in 1919. The USACE operates and maintains the Soo Locks. The McCarthy Lock was built in the 1940s and is too small for larger ships carrying iron ore. The larger, 50-year-old Poe Lock serves the Great Lakes freighters, 1,000-foot or longer boats, which carry as much as 584 train cars. The USACE has decommissioned the Sabin and Davis locks, located north of the Poe Lock. The new lock will replace them.

“We are operating off of a single lock that is beyond its design life,” Miller said. “The purpose behind the new lock project is to provide some relief and risk reduction for over-reliance on a piece of aging infrastructure at the Soo.”

| Your local Trimble Construction Division dealer |

|---|

| SITECH Michigan |

Additionally, a second lock will enable the USACE to provide some maintenance on the Poe Lock. At present, such work can take place only during the winter from January to March, when the lock is closed.

Contractors have completed two phases of the New Lock at the Soo program to work on the upper approach to the north channel. All of the locks are gravity fed, with no pumps. The USACE’s Inland Navigation Design Center, with engineers located across the country, designed the project.

First, Trade West Construction of Mesquite, Nevada, deepened the upstream approach from 24 feet to 30 feet under a $52 million contract. The contractor removed bedrock, which is 1,000 feet thick under the locks, and completed it in August 2022.

During the second $117 million phase, Kokosing-Alberici — a joint venture between Kokosing of Westerville, Ohio, and Alberici Constructors, headquartered in St. Louis, Missouri, with offices in Detroit, Michigan — rehabilitated the north side of the approach wall and narrowed it to feed just one lock, not the original two. The job also required creating space for ships to moor. The project, with its 4,800 linear feet of walls, consumed 62,000 cubic yards of concrete. The team built an onsite batch plant, due to the job site being in a rural area with limited availability of concrete and the need to produce a specific mix held to tight tolerances. This phase was substantially complete in September 2024.

| Your local Deere & Co dealer |

|---|

| AIS Construction Equipment |

The project sits in an active river. The USACE aims to minimize any negative impacts to shipping, fishing, or other marine traffic.

The USACE awarded a $1.8 billion contract for the new lock in summer of 2022 to KAT, a joint venture among Kokosing, Alberici, and Traylor Bros. of Evansville, Indiana. The three companies work as a fully integrated team, along with its subcontractors. KAT commenced construction in July 2022.

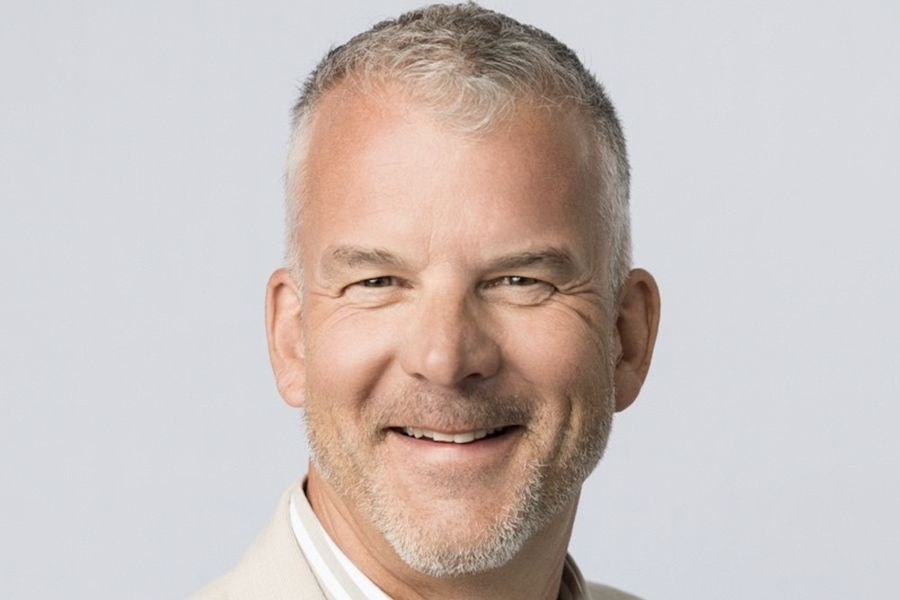

“I am proud of the team we are building,” said Auston Stromberger, Project Executive for KAT. “Building a good team and partnership is huge and makes us want to come to work every day.”

That work includes demolishing and deepening the decommissioned Sabin Lock and constructing a 1,200-foot-long, 32-foot-deep, and 110-foot-wide new lock; a new pump well to serve the entire facility; and a bridge to the onsite hydropower plant.

| Your local Trimble Construction Division dealer |

|---|

| SITECH Michigan |

The demolition and deepening required installation of cofferdams upstream and downstream; installation of a soil and bentonite wall on the north side of the Sabin chamber; curtain grouting to prevent seepage into the excavation by injecting grout into the wall; and dewatering the site. KAT completed this work in May 2024, allowing demolition to start.

Some blasting occurred in summer 2023 and winter 2024 to fracture the bedrock for a new utility shaft and excavation for the new lock. KAT primarily uses mechanical means with a large trencher, hoe rams, and milling equipment for the demolition. The team recycles the excavated concrete, piling it on site.

USACE monitored vibration to ensure vibrations did not damage historical buildings on site or Atlantic salmon and lake sturgeon habitats near the hydroelectric plant. Crews also avoided blasting within 12 hours of a concrete pour. Demolition is about 75 percent complete. There are about 10 cranes on site, and the team currently is adding three tower cranes to achieve the space needed during monolith construction for placing formwork, installing embedded metals and reinforcing steel, and pouring concrete.

KAT rented dock space upstream and downstream and has rented vessels and contracted with a tour-boat operator to bring crews to and from those docks to the job site. The site comprises 1.98 miles in length, requiring the busing of workers from one area to another. Work continued through the winter of 2024-2025.

| Your local Trimble Construction Division dealer |

|---|

| SITECH Michigan |

“We had a very successful winter this year,” Stromberger said.

The team has completed the first two of 84 monoliths, large concrete structures that are about 44 feet wide and 80 feet tall, which form the walls of the new lock. Each monolith requires 14 mass concrete lifts.

KAT recruits locally and teaches new people how to work construction.

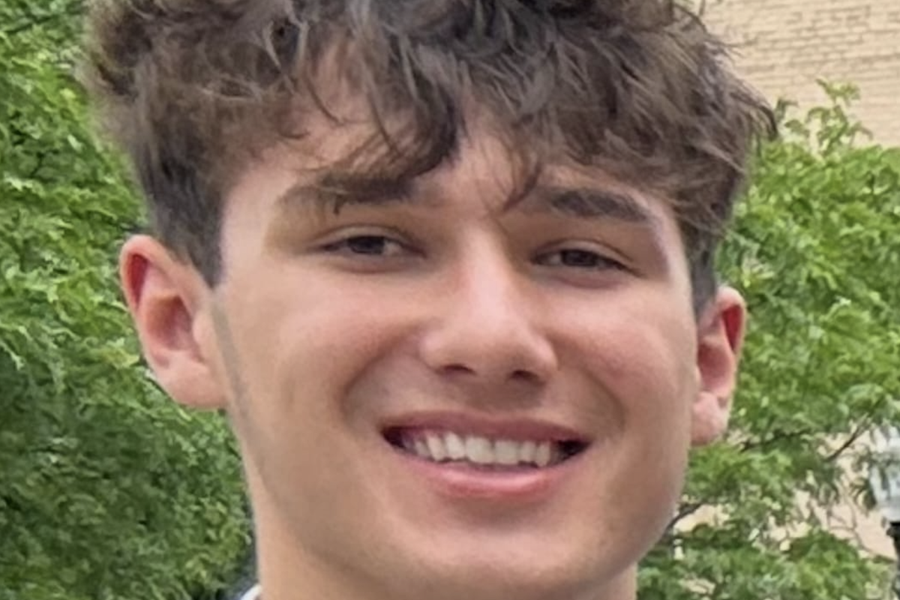

“When we come into a new area, we want to have as much local participation as possible,” said Jeff Hartman, Construction Manager for KAT. “We place a real focus on hiring local construction workers and bringing in people who might be new to construction. ... Then when we are done here, there will be a large group of skilled tradespeople who will remain and support the community and its construction needs. We are proud to be able to contribute to the local community and workforce.”

| Your local Trimble Construction Division dealer |

|---|

| SITECH Michigan |

At the end of March 2025, 160 workers were on site, with a peak expected this year of 300 to 350 workers.

“One of the things I am proud about is we have formed a cohesive team,” Hartman said. “These projects are challenging to build. There are a lot of stakeholders. We have formed a good partnership with the U.S. Army Corps, local stakeholders, and unions. ... There is something about this project that brings people together. It’s vital to keep the economy running and [for] national security.”

The project remains on track to complete in the summer of 2030. Additional contract options are possible.

“The Soo Locks are a center piece of Sault Ste. Marie, so we have a lot of public support for this project, which is helpful,” Miller said. “They understand how important an additional lock will be.”

| Your local Trimble Construction Division dealer |

|---|

| SITECH Michigan |

Photos courtesy of USACE