According to the Ohio Department of Transportation (ODOT), the Buckeye State annually supports the sixth highest total vehicle miles traveled, the sixth highest freight volume, and maintains the fifth largest interstate system in the United States.

“We’ve been working on this project for years, and there is so much traffic,” said Kathleen Fuller, Public Information Officer at ODOT. “This overhaul has been needed.”

Phase 8 consists of five different phases, including the reconstructing of I-75 from Glendale-Milford Road to the Kemper Road overpass, adding a fourth lane in each direction, adding capacity at the Sharon Road interchange and at Sharon and Chester roads, and adding two new bridges. The project began in the summer of 2021 and is scheduled to be completed by September this year.

Paid for through the department's Major Rehabilitation and Major New programs by the Transportation Review Advisory Council at a cost of $46 million, it is one of the largest contractual projects to date for heavy civil construction company, Sunesis.

| Your local Trimble Construction Division dealer |

|---|

| SITECH Michigan |

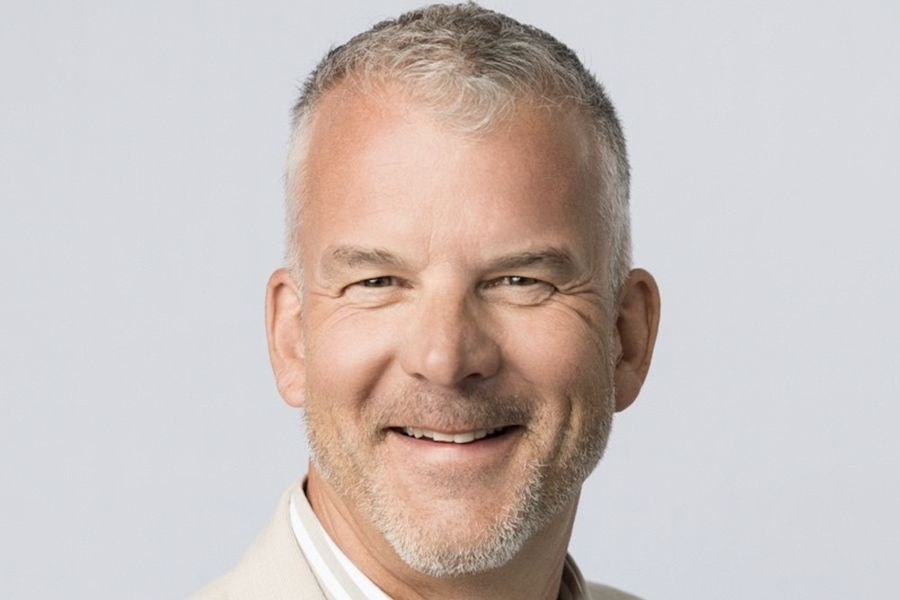

“We've done interstate jobs, but never of this scale,” said Bill Pond, Senior Project Manager at Sunesis Construction. “I’d say it is one of our largest jobs from the complexity of the highway standpoint.”

Two new bridges on I-75 that go over Sharon Road had to be constructed in two distinct phases; the old bridges had to be demolished while a portion of them were still left in service. Sunesis needed to remove approximately one-third of an existing bridge to gain space for the new bridge, as the new one would be almost 30 feet wider.

The new bridges were built next to the existing bridges, only taller and wider. The construction was elevated 5 to 6 feet next to the traffic below while they were building the new roadway, needing to ensure nothing fell over onto the roadway and drivers below.

To keep the bridges operational during the construction, the contractor built the outside half of the new bridge, then switched the drivers to the inside. Sunesis kept the bridge as three lanes, but then slid drivers all the way over to the lefthand side of the bridge, essentially leaving no shoulder.

They also removed approximately 12 feet of the existing bridges, consisting of the deck, a few bridge beams, and one of the piers — all while it remained in service. Each new bridge had eight pre-cast concrete I-beams that weighed almost 200,000 pounds. The contractor used excavators and tandem picks with large cranes to perform the bridge work.

Sunesis installed wire walls comprised of a wire mesh basket that uses soil reinforcement strips, called geogrids. These walls can go up to 40 feet, are relatively inexpensive, and are quick to install.

“We had already used geogrids as part of another scope of the bridge, and we were able to work with ODOT and translate that design into this roadway section and just keep on moving, not delaying anything,” Pond said.

Pond also said they had to perform a surcharge to compress the roadway’s underlying soil over a 30-day period. Immediately behind the bridge abutments, Pond’s team had to fill to finish the grade of the road with soil, as well as surcharge the soil immediately below that section of the roadway.

“That’s how you get settlement out of the soil before you ever build your permanent asphalt roads or your approach slabs, etc.,” Pond said. “The problem with that system is you surcharge the area, but then you have to remove some of these things. You still have more work to do and things to build on top of that area.”

“We had a space that had to be filled with a whole bunch of weight, but that space needed to be utilized later for the bridge abutment footing and the bridge abutment walls, and that's where the beams from the bridge sit,” he added.

Sunesis worked with Hilltop Concrete, a local ready-mix supplier, to utilize over 500 2-foot by 6-foot ready-made concrete blocks. Using excavators, Ponds’ team stacked the blocks in place.

“We basically stacked them in this space and then let them sit there and do their thing for 30 days while that surcharge took place, and then we removed them all,” Pond said. “We had never had to surcharge an area that had to have a removable component to it. And when you remove something, you want it to be quick and easy. Soil is messy, so blocks worked out well.”

“You have a lot of clay soil, but we also get a lot of sand and gravel. It's a mixed bag here,” Pond said. “When you find shale, you have to bear it. It has to be excavated to a certain depth and then replaced with suitable soils. That impacts roadway construction and drives cost up because you have to get it out of your way.”

That experience paid off for Ohio’s Thru-the-Valley Megaproject. Every construction project has specifications that contractors need to know, but according to Pond, ODOT’s are unique.

“Ask questions,” Pond advised to other contractors working in the state. “We were successful at getting some specifications modified because of this project. We pursued different techniques on how to install some certain types of roadway applications when it came to concrete paving, and they worked with us. We were actually able to get some of the specifications modified because of the challenges we had, which should help other contractors in the future, and hopefully us as well.”

Phase 8 of the I-75 Thru-the-Valley Megaproject is scheduled to be complete in September of this year.

- Owner: Ohio Department of Transportation

- Contractor: Sunesis Construction Company, West Chester, Ohio

- Key Subcontractors: Security Fence (guardrail, fence, signage, and electrical), Barrett Paving (asphalt paving), A&A Safety (maintenance of traffic, striping), Blackswamp Steel (rebar installation), Twin Rivers (concrete sealing), ECS Midwest (compaction and concrete testing), Capitol Tunneling (jack and bore piping), Mt. Carmel Stabilization Group (cement stabilization), Tri-State Concrete Sawing (saw cutting), BOCA Construction (asphalt milling and grinding), Oglesby Construction (concrete curb and sidewalk), GRL Engineers (pile testing), Spartan Construction (pipe inspection), McGill Smith Punshon (engineering and surveying)