Since then, MDOT has performed ongoing maintenance activities such as pothole repairs. However, it has become cost-prohibitive to continue efforts to rehabilitate the pavement for the motoring public.

“The rehabilitation of I-696 that was completed was done in an attempt to extend the limited life left in the pavement such that traffic could be maintained until this reconstruction project could be designed,” said Brian Travis, a Construction Engineer with MDOT.

Along the nearly nine-mile-long project area, the pavement condition will be restored. In addition, seven bridges are being repaired to extend their service life as well as to improve drainage, sewer, guardrail, and signage.

Two bridges over the Rouge River are being reconstructed. The upper branch of the 127-mile river is in the vicinity of the project.

| Your local Trimble Construction Division dealer |

|---|

| SITECH Michigan |

Other project elements include concrete curb and gutter, sidewalks, sidewalk ramps, culverts, sewer, drainage, steel piling, steel sheet piling, cofferdams, guardrail work, signage, and pavement markings.

The corridor experiences significant traffic. The average daily traffic for the corridor peaks at 190,000 vehicles and is forecasted to exceed 201,000 in 2042.

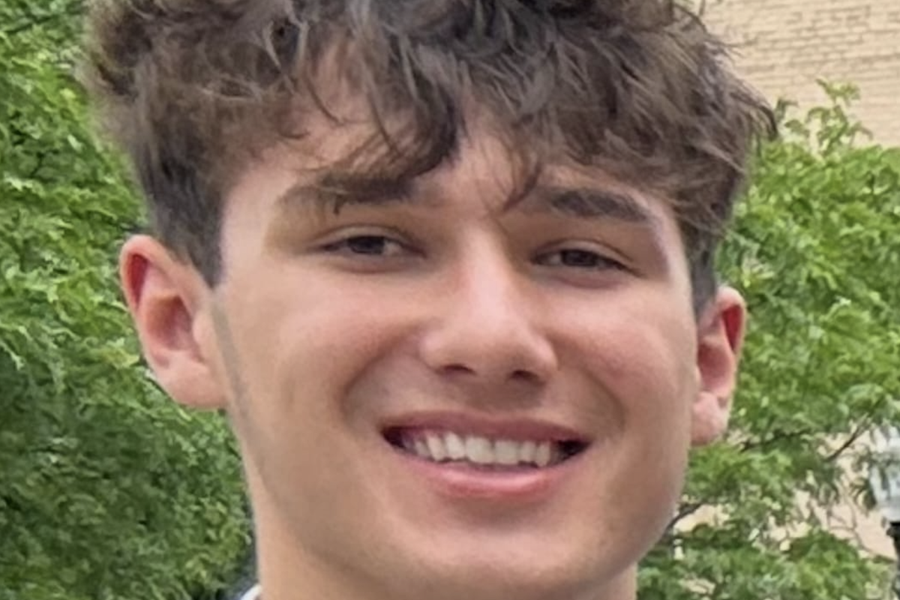

“The purpose of the training was to provide potential bidders a head start, and included assistance with installing the software, a preview of the I-696 over Rouge River files, and training on how to navigate the models,” Hall said. The Digital Delivery pilot consists of the reconstruction of two bridges (I-696 eastbound and westbound) over the Rouge River in the City of Southfield. Over the last decade, MDOT — in conjunction with local contractors — has implemented digital workflows for project delivery. The focus has been on producing engineering data models.

Hall noted that implementation of the BIM Execution Plan, which had to be created by the contractor and subsequently approved by MDOT, is one of the most unique aspects of the project.

“With this being a pilot project, the BIM Execution Plan was a collaborative effort through multiple revisions to get a formal plan approved before the start of construction,” Hall said. “It was up to the project team to train all of our key foreman on how to utilize the 3D modeling software.” C.A. Hull held daily training sessions to equip them with the necessary knowledge for building back the structures.

The BIM Execution Plan defines how the model files will be utilized for the construction of the 3D-modeled bridges. The purpose of the plan is to provide insight into all furnished labor, equipment, training, qualifications, meetings, engineering, supplemental details, submittals, and other services necessary to utilize electronic or other computer-generated models during the construction phase.

The team used some complex and complicated equipment and machinery on this project. The project required driving an H-pile 110 feet into the earth for the abutment foundation of the I-696 over the Rouge River bridge. They had to drive over 20,435 linear feet of pile, consisting of over 261 full-penetration weld splices.

“To drive the pile into the earth, we were required to utilize complex equipment, including a D46-32 diesel impact hammer,” Hall said. “Utilizing this piece of equipment to drive the battered pile into the earth can be extremely complicated, as the impact hammer can weigh up to 45,000 pounds.”

The project is a good fit for C.A. Hull because of its location, size, and complexity. The firm also had other incentives. “Whenever we get the chance to team with our partners at Dan’s Excavating and Ajax Paving, there is another level of motivation to get the job,” said Jim Reed, Director of Project Management for C.A. Hull. “By being part of the solution, this team has successfully constructed a lot of large-scale projects for MDOT.”

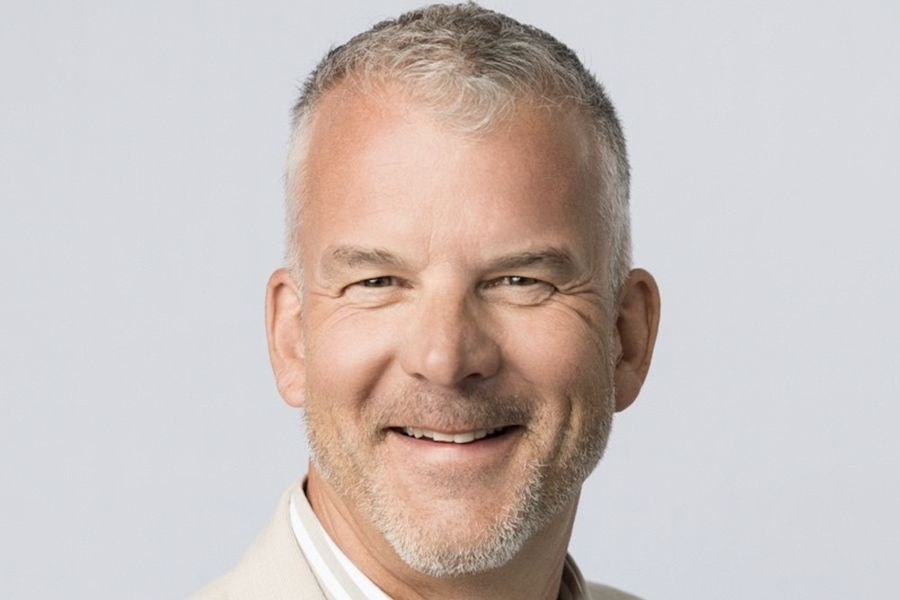

The state and its representatives have appreciated the work of C.A. Hull and the rest of the team. “C.A. Hull has not only performed the contract work required, but has also looked for opportunities to streamline the project schedule to compress the duration of the work while still achieving the project goals,” said Steve Griffith, HNTB Consultant. The firm is managing the project for MDOT.

“C.A. Hull sequenced their repair operations with the freeway closures such that the work on the Orchard Lake Road structure could be completed entirely in the 2023 construction season, which will result in minimal impacts to Orchard Lake Road and the motoring public in 2024,” Griffith said.

Changes like the one noted above have allowed the team to be ahead of schedule. Originally bid as a three-year project (2023 to 2025), the team has made changes (with MDOT’s approval) to the scope of work to make it a two-year project. Hall credits MDOT’s willingness to partner with the contractor on critical time-sensitive operations, thus enabling the changes to happen.

“The key to keeping this project on schedule is implementing and enforcing pre-planning by not only weeks, but months in advance of performing critical operations,” Hall said. “The key to pre-planning so far in advance is being able to make adjustments on the fly as to how we complete tasks with the manpower required, in a timely and cost-effective manner.”

The state funds are part of the Rebuilding Michigan program. According to MDOT’s website, the $3.5 billion program is “focused on rebuilding state highways and bridges that are critical to the state’s economy and carry the most traffic.”

As of the writing of this article, the project is on budget. Griffith credits the team. “The contractors have been working in an efficient manner to the high-quality standards, as confirmed by the construction oversight team,” he said.

“Our team prides itself on consciously saving time and money on every operation and task we perform,” Hall added. “In conjunction with that, we perform daily operations with qualified individuals while ensuring a safe work environment at all times. By implementing that methodology of work, we are essentially able to free up more manpower to perform other critical tasks, which allows us to accomplish more work in a single day.”

This project will result in multiple benefits. The motoring public will have access to the new concrete pavement established by this project for many years of use, with little to no interruptions to traffic flow by maintenance or construction-related activities. This will eliminate user delays and costs that would have resulted from ongoing efforts to keep the existing pavement in service. The public will also benefit from a variety of enhancements to safety, commerce, and connectivity throughout the area.

- Owner: Michigan Department of Transportation; Brian Travis, MDOT Construction Engineer

- General Contractor: Dan’s Excavating, Shelby Township, Michigan

- Bridge Construction: C.A. Hull, Commerce Charter Township, Michigan

- Paving: Ajax Paving, Troy, Michigan

- Project Designer: Bergmann Associates, Lansing, Michigan

- Other Key Consultants: Michael Baker International, Pittsburgh, Pennsylvania; HNTB, New York, New York; Great Lakes Engineering Group, Lansing, Michigan