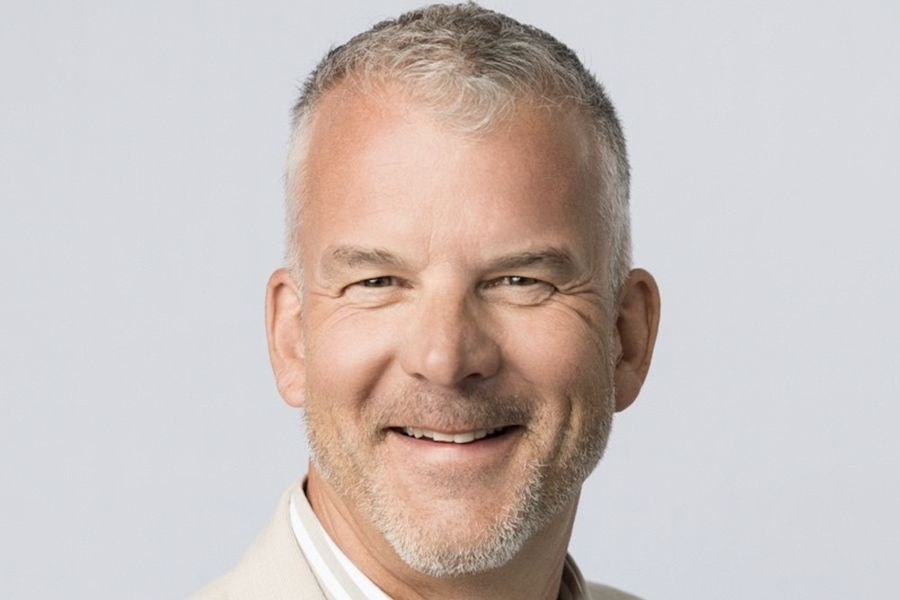

“From small commercial sites to large mining projects, we have the capabilities to handle it,” said Pinney, who is the President of the Skiatook, Oklahoma, business that he co-owns with his father, Tim. “On the commercial side, we take a property from bare ground to the point where our customer can start the building process. That includes clearing, putting the site to grade, and installing utilities. Mining projects vary from overburden removal and initial mining to reclamation.”

Pinney Dozer Service works in about a 500-mile radius of Skiatook, completing jobs in Oklahoma, Kansas, Texas, and Arkansas. The firm’s 40 employees are split into four dirt crews and a utility crew.

“Our goal last year was to hit the $10 million mark, and we did,” said Pinney. “Previously, our highest revenue year was $8 million. Our main market, which is the Tulsa area, has been great for construction for several years, and that’s actually really helped us expand. We have developed a sizable list of repeat customers who continuously call us back. As they have grown, we have grown with them.”

For decades, that’s been part of the Pinney family’s formula for success. Pinney’s grandfather Jerald Harvel started a utility contracting business in Skiatook in the early 1970s. Tim joined the company and helped build an earthwork division, then branched out on his own to form Pinney Dozer Service in 1998.

| Your local Trimble Construction Division dealer |

|---|

| SITECH Michigan |

“Dad ran by himself for several years, and early on, the focus was agricultural and then some residential,” recalled Pinney. “When I came on board in the early 2000s, we started to add employees and grow more with an emphasis on commercial, industrial, and mining. As we did, we retained most, if not all, of our previous customers and continued to build our list. It seems like everyone we work with likes our services and the fact that we control the sitework schedule, so they don’t have to rely on multiple contractors.”

“All of our guys are trained to use GPS, and it’s really been a time-saver in terms of surveying and moving dirt faster and more accurately,” he said. “More recently, we adopted digital technology into practically everything we do, which gives us time and cost savings. For instance, all our plans are digital, so we don’t have to print off multiple sets of plans.”

Pinney Dozer Service builds some of its plan models and relies on outside companies for others. In either instance, it takes the files and uploads them to its Komatsu intelligent Machine Control (iMC) equipment with integrated GPS grade control. Pinney Dozer Service currently uses D51EXi, D61EXi, and D65EXi dozers – as well as PC210LCi excavators – to do everything from stripping to trench digging to finish grading.

“Once the plans are uploaded, we’re ready to hit the ground running,” said Pinney. “One of the biggest advantages is that there is no guessing. The machines always know where they are in relation to finished grade without surveying or a grade checker. We’re moving dirt once and doing it accurately. The intelligent machines have cut our time to finish and our costs by 20 percent to 30 percent. We’re consistently seeing that across all our projects.”

Pinney continued, “One area where we have seen big savings is in material placement, such as putting down aggregate base or bedding. It used to be within a tenth or two. The intelligent machines helped us tighten that up to being right on the money. Now, when we bid a project for a certain amount of rock, that’s what we use. We don’t have to figure in any overage.”

“They are especially useful in those situations where you are putting in utilities up against a building or working around traffic,” explained Pinney. “They have excellent power and lifting capacity without the worry of a counterweight potentially hitting something when you swing the machine.”

Pinney purchased all the Komatsu equipment from Kirby-Smith Machinery Inc. (KSM) with the assistance of Tulsa-based Territory Manager Peyton Chatham, who also helped Pinney Dozer Service’s staff learn how to track product, fuel, and other critical data with Komatsu’s Komtrax telematics system.

“Komtrax is a great fleet management tool,” said Pinney. “Our mechanic can see when a machine is close to a service interval. Kirby-Smith tracks the machines too, and if there is any issue, our mechanic can work with Kirby-Smith’s service team to resolve it – usually over the phone, even if it’s hundreds of miles away.”

Services for the newer Komatsu machines are handled by KSM’s technicians through Komatsu Care, which Pinney Dozer Service appreciates because it ensures they are done on time.

“Service is a huge factor when we buy our equipment as well as parts availability,” said Pinney. “With Komatsu and Kirby-Smith, we haven’t had any issues whatsoever — whereas with other brands, we’ve had major issues and had to wait weeks or months for service. Kirby-Smith has never been like that.”

“There seems to be more of a profit on the mining side of things,” explained Pinney. “With a commercial project, you usually come in, work on it, and it’s over with. With a mine, you get to create the mine, and you get to clean it up too, so there’s a lot more to do.”

“We’re not planning on growing a whole lot more with the present economy,” said Pinney, “but we don’t have any plans of slowing down.”