When Alterman Electric, a 100-year-old company headquartered in San Antonio, Texas, recently faced a year of complex, difficult projects, inconsistent outcomes and operational strain prompted leadership to take action. They brought in consulting partners to examine everything from order-to-cash processes to real-world field productivity. What they discovered reshaped Alterman’s future.

To better understand what was limiting production, Alterman built a controlled laboratory environment inside its shop. Materials, tools, drawings, and job conditions were fully prepared in advance. Field electricians ranging in experience from apprentices to seasoned veterans performed standardized in-wall rough-in installations under observation.

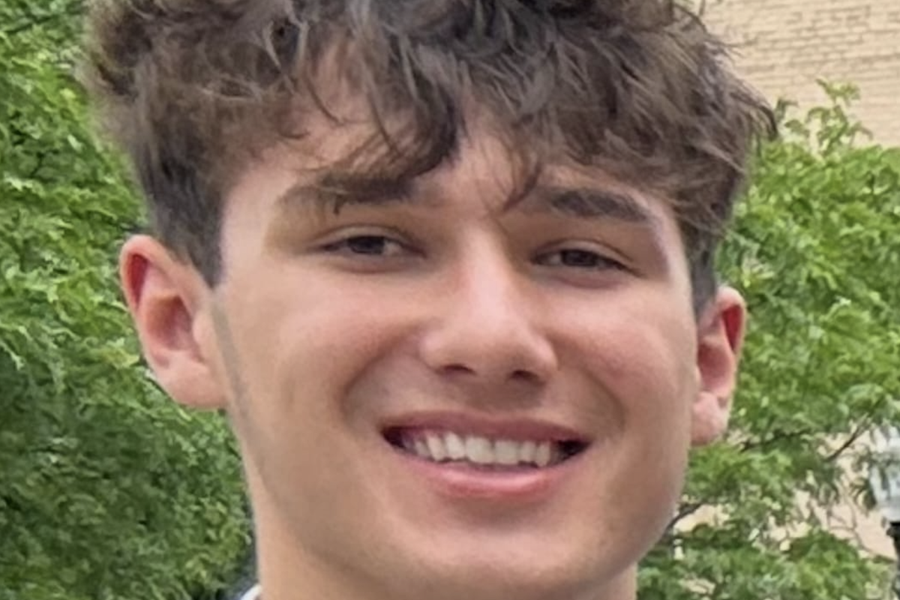

“When we ran the controlled test, every electrician — no matter their experience level — beat the estimated installation time by at least twofold,” said Eric Walker, Alterman’s Director of Strategic Workforce Solutions. “That was the turning point. It proved our people weren’t the problem; our processes were.”

In real-world conditions, electricians face constant interruptions — missing materials, unclear drawings, late design changes, safety obstacles, and logistical delays. In the controlled environment, those distractions disappeared and productivity surged. This insight became the foundation of the Packaged Alterman Construction Kit (PACK).

“PACK takes thousands of decisions out of the field and brings them upstream, where they can be standardized, coordinated, and optimized,” Walker said.

| Your local Deere & Co dealer |

|---|

| AIS Construction Equipment |

Instead of requiring foremen to interpret drawings, plan layouts, source materials, and manage crews simultaneously, now Alterman’s Virtual Design and Construction group of more than 65 employees drives the PACK effort. Through fully coordinated 3D models, Alterman claims needed space early in construction, ensuring that electrical pathways are protected from mechanical, plumbing, or fire system conflicts.

Assemblies are digitally placed using Revit and extracted into fabrication workflows through Stratus. Each component is specifically built for its final location.

The full PACK system includes fabrication, kitting, and just-in-time logistics.

Each project is broken into weekly work zones. For each zone, Alterman fabricates precise assemblies then packages the exact materials needed into kits. These kits are delivered to the job site two days before installation — never more than one week of inventory on site.

| Your local Trimble Construction Division dealer |

|---|

| SITECH Michigan |

A dedicated logistics team manages delivery across San Antonio, Austin, Dallas, and regional markets. Larger production flows from the San Antonio shop, while Austin and Dallas maintain smaller support facilities, with major expansion underway.

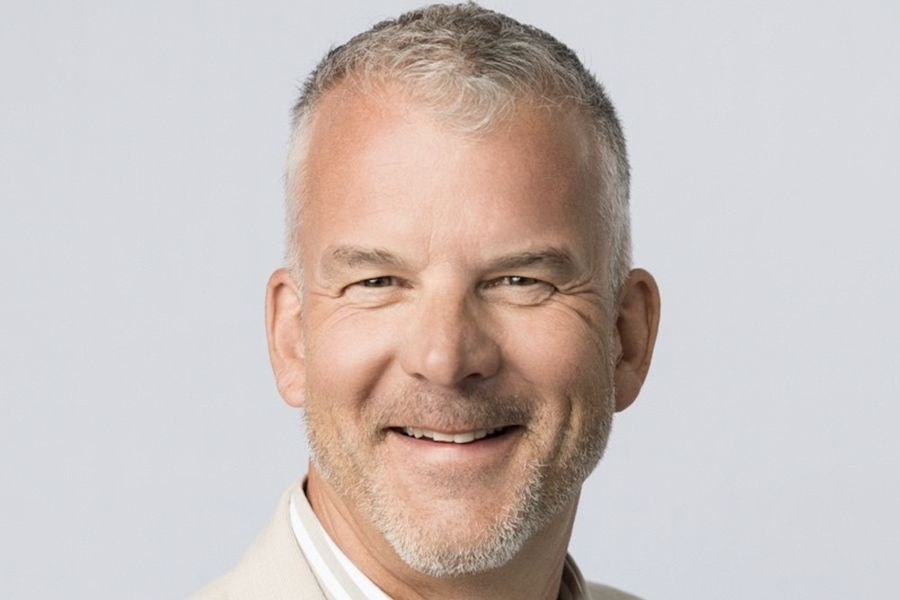

“Everyone on the job site has the tools, materials, and information in their hands at the right time and in the right place to maximize production,” said Greg Padalecki, Alterman’s CEO. “Anything less than that creates distraction.”

PACK provides structure to the ever-evolving workforce. Alterman has hired more than 900 people in a single year, and roughly half the field workforce now has less long-term tenure with the company. The number of apprentices more than doubled over the past decade.

By delivering a consistent workflow for each crew, PACK improves safety planning, increases predictability, and compresses learning curves, the company said.

| Your local Deere & Co dealer |

|---|

| AIS Construction Equipment |

In addition, a continuous feedback loop exists between the field and the PACK planning teams. When a kit misses the mark, information moves quickly upstream. When improvements are discovered, they become standardized across the organization.

“The process has to be consistent, and it has to feel the same on every job,” Padalecki said. “That consistency is what builds trust in the field.”

PACK’s impact can be seen in Alterman’s work on large-scale data centers. Alterman now supports multiple data center builds, often in parallel across Texas. Some individual facilities reach 200 megawatts of electrical capacity, requiring thousands of electricians. PACK’s centralized planning, fabrication, and logistics allow Alterman to achieve this level of scale safely, consistently, and profitably.

“The biggest value PACK brings is predictability,” Walker said. “When our foremen focus on building — not chasing parts or interpreting drawings — we can scale faster, reduce delays, and support larger volumes of work than ever before.”

| Your local Deere & Co dealer |

|---|

| AIS Construction Equipment |

The company also hopes that PACK supports the electrical profession’s long-term future by removing job site waste and distraction, allowing electricians to focus on craftsmanship, safety, and quality.

“I’m a die-hard believer that a rising tide lifts all ships,” Padalecki said. “I love showing people how we do it — and learning how others do it too — so we can all get better together.”