Currently, the roadway is poor quality and congested during peak travel hours. In addition, the area south of Sacramento is expected to experience population growth, so the project will help ensure that the roadway is sufficient to meet that demand.

The main aspects of the project include rehabbing the pavement, constructing new HOV (carpool) lanes in each direction, replacing a pedestrian overcrossing, constructing two sound walls, installing new fiber optic lines, new ramp meters, and extending various entrance and exit ramps. Auxiliary facilities, including drainage systems, overhead signs, lighting, guardrails, and safety barriers were upgraded and replaced.

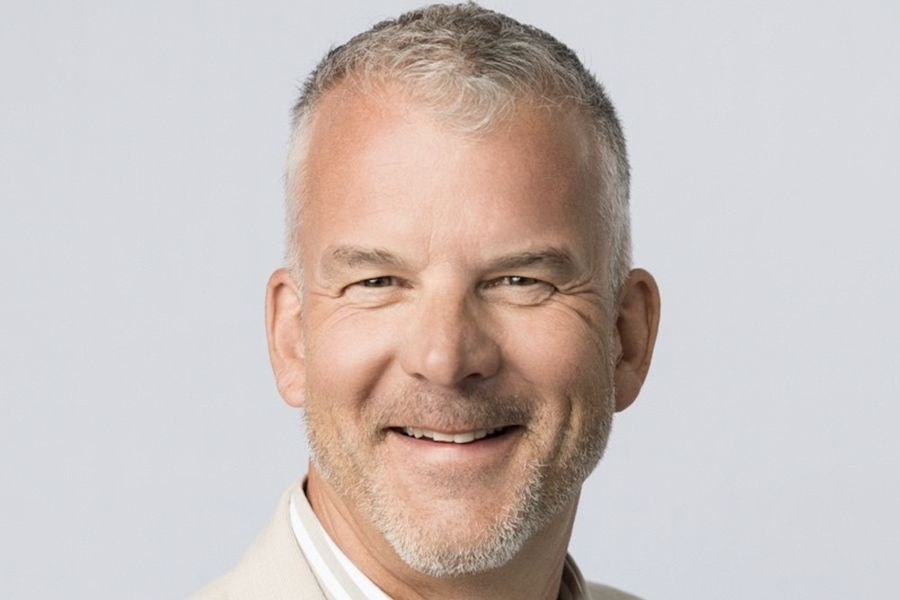

“Upon completion of the project, we expect there will be a 13-minute reduction in commute time for those who use the HOV lane and a 7-minute reduction for the other lanes,” says Jess Avila, a Project Manager for Caltrans who is overseeing the project. “Installing auxiliary lanes between interchanges for local traffic will also help facilitate the reduced travel time.”

The pedestrian overcrossing the team replaced used spiral stairways to cross from one end of the freeway to the other. The new pedestrian overcrossing is ADA compliant. The team received input from the community regarding the aesthetics.

| Your local Trimble Construction Division dealer |

|---|

| SITECH Michigan |

Work has also been taking place on the weekends. There have been 13 weekends where there was a partial closure for 55 hours to get major work done. “While there has been some backup, we did this on the weekend because there’s typically less traffic,” Avila says. “We made sure to get the word out to the public, so they would know what to expect.”

It also required coordination among stakeholders, including freeway service patrol. Avila notes the project had a robust public information program. Partnering played a major role in enhancing communications between the contractor and Caltrans personnel. He gives a good deal of credit to the contractor with whom they have had an ‘amazing partnership.’ The partnering was facilitated by Global Leadership Alliance (GLA).

“We had a long-life pavement designed to come to a certain distance to a bridge approach slabs which were to be modified with extra-long precast approach slabs,” Avila says. The prefabbed slabs were to be brought to the site for installation, which would be a good deal of work and require substantial time to install. “The contractor proposed bringing the long-life pavement to the bridge ends, so the precast slabs and the work related to them were not necessary.” This impacted 14 locations.

Another challenge to the schedule was the decision to use long-life hot mix asphalt, to extend the life of the pavement. The long-life hot mix asphalt mix consists of three different design layers. The pavement was designed by University of California Pavement research center and Caltrans Pavement Division in collaboration with Caltrans D3. “A fourth asphalt layer used is noise reducing, allows water to soak in the pavement, and reduces splash,” Avila says.

The contractor put the mix together at the plant. Both companies that make up the joint venture own concrete, asphalt, and gravel plants near Sacramento. The contractor’s laboratory personnel needed training on the testing requirements. It took several iterations (sampling and testing) before successfully achieving an acceptable mix design. In addition, because it is three different asphalt layers (rather than the standard one), it takes more to lay down.

| Your local Deere & Co dealer |

|---|

| AIS Construction Equipment |

The $370 million project has received funding from multiple sources:

- SHOPP (State highway operations protection program): $280 million

- SB1 (state bill) (SHOPP/SCCP): $48.3 million

- STA (Sacramento Transportation Authority) Local Measure A (Local sales tax): $33.2 million

- SACOG (Sacramento council of governments) (CMAQ) $8.5 Million

The project has gone over budget, and the final number is expected to be $388 million. This is due to change orders. The primary change order is related to a section of I-5 that goes through downtown Sacramento and is known as the boat section because it was built below the water table. The depressed U-shaped structure is kept down by concrete piles. The team upgraded the median barrier, drainage systems, and overhead signs. The costs related to this were higher than anticipated.

Soon commuters using I-5 in and around Sacramento will enjoy greater mobility and be able to reach their destination more quickly and safely.