Interlochen Center for the Arts in Green Lake Township, Michigan, connects students of all ages with multidisciplinary arts education, but with its pine-filled grounds nestled between two lakes, only a busy road connected the two parts of campus — until Team Elmer’s of Traverse City, Michigan, constructed a huge box culvert pedestrian tunnel to provide safe access under J. Maddy Parkway in Grand Traverse County.

The 104-foot tunnel was assembled from 13 massive precast concrete sections. “A typical box section was 8 feet long and each weighed 76,800 pounds,” said Eric Sanborn, Project Manager for Team Elmer’s.

To accommodate the new structure, Team Elmer’s raised the surrounding roadway more than 4 feet. A strict timeline compounded excavation and installation challenges. The tunnel and road pavement reconstruction needed to be finished in a four-week window prior to a scheduled detour onto J. Maddy Parkway for a nearby Michigan Department of Transportation (MDOT) project.

Team Elmer’s completed the 2.7-acre project under a negotiated contract, accommodating ongoing campus operations with minimal disruptions and even opening the roadway early.

Established in 1928, Interlochen Center for the Arts offers an internationally recognized residential arts academy for high school students, summer camps for grades 3-12, and continuing education opportunities for all ages in music, theater arts, visual arts, creative writing, dance, film, and new media.

| Your local Trimble Construction Division dealer |

|---|

| SITECH Michigan |

Previously, students, staff, and visitors needed to stop traffic at a crosswalk on J. Maddy Parkway to travel between Interlochen’s Green Lake and Duck Lake campuses. To provide a safer, more connected, and accessible campus, Interlochen explored various options before settling on the box culvert tunnel.

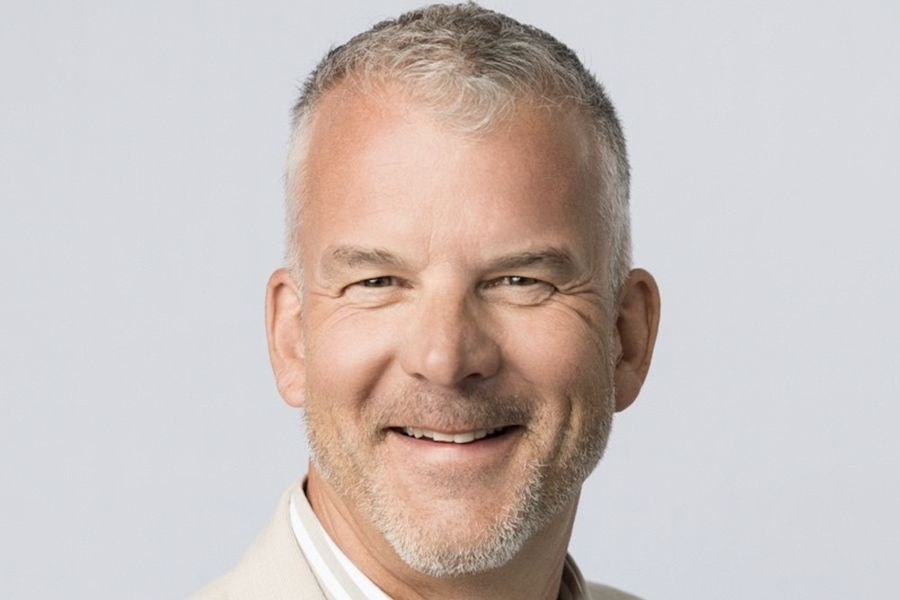

“Once we decided on a tunnel, there was the concern about people feeling safe and not claustrophobic when using the tunnel,” said Eric A. Gray, PE, Interlochen’s Executive Director of Facilities and Maintenance. “We tried to address those concerns by increasing the size of the tunnel, raising it up out of the ground to provide a more open/shallow decent at the entrance and exits, and installing a lighting system that will adjust to the time of day to make sure it feels bright and open.”

In addition to the 24/7 lighting system, security cameras and an emergency phone at the center of the tunnel help ensure safety. To avoid future stormwater issues, large underground infiltration systems were installed on both sides of the tunnel.

Designers also made sure the tunnel’s entrance and exit pathways met ADA requirements, with a 5 percent or less grade. The tunnel provides a roomy interior height of approximately 9.5 feet and a width of 18 feet.

| Your local Deere & Co dealer |

|---|

| AIS Construction Equipment |

“Being the school that we are, we are working with our students and staff to come up with some artist touches for inside the tunnel that will really make our tunnel unique with a bit of an entertaining experience while traveling through it,” Gray said.

Construction for the project started on August 6, 2025, with an inflexible roadwork deadline of Labor Day (September 1, 2025). MDOT detoured traffic onto J. Maddy Parkway on September 2 as they worked on nearby U.S. 31.

Meeting that deadline for the first phase of the project would not have been possible without the full closure of J. Maddy Parkway and detours around the work site.

“Building the project half-width while maintaining one lane of traffic would not have allowed that timeline to be met,” Sanborn said.

| Your local Trimble Construction Division dealer |

|---|

| SITECH Michigan |

However, coordinating detours during a busy time with summer traffic was a significant logistical challenge managed through careful planning and coordination with local authorities, including the Grand Traverse County Road Commission and Green Lake Township.

In addition, “The design of tunnel materials was a direct result of the need to expedite the installation of the physical tunnel sections so that we could minimize the time needed to have J. Maddy Parkway closed,” Gray said. “We made sure that all the materials were on site or verified to be at specific vendor facilities so that there were no delays waiting on anything.”

Team Elmer’s coordinated closely with all parties. “Northern Concrete Pipe created a spot in their production schedule in order to meet the timeline,” Sanborn said. “Crews, material suppliers, and subcontractors all worked hard to meet the schedule and the weather cooperated.”

The culvert sections were delivered to the job site via 13 semi-truck loads over a two-day period. Team Elmer’s meticulously planned out placement, resulting in a more seamless installation.

| Your local Trimble Construction Division dealer |

|---|

| SITECH Michigan |

Before the installation, crews used an open cut system to remove 3,400 cubic yards of material for the tunnel and tunnel ramps on each end, stockpiling the material on site for later use in backfilling and covering the tunnel. According to Sanborn, the closed road system allowed for an adequate angle of repose, and the open trench aided access in positioning the culvert. An additional 7,778 cubic yards of fill sand was imported for the 4-foot road grade adjustment.

After excavating, Team Elmer’s installed a stone base, then utilized a Liebherr LTM 1160-5.2 Mobile Crane to unload and place each of the culvert sections.

“This size of crane was needed due to the size and reach location on site for each 76,800-pound section,” said Kent Megill, Crane and Rigging Manager for Team Elmer’s.

In order to accommodate the crane, the project required temporarily relocating overhead power and fiber lines. Consumers Energy, Merit Network, and Western Telecom were integral in this temporary relocation process, allowing an accelerated tunnel installation timeline as planned. After placing the culvert pieces, the utilities installed conduits for electric and data before Team Elmer’s covered the tunnel.

| Your local Trimble Construction Division dealer |

|---|

| SITECH Michigan |

Roadway work started with pulverizing existing materials. Team Elmer’s used that crushed material, as well as excess from the excavation, to raise the new roadbed, allowing a smooth transition from the existing road elevations on each end.

In addition to the reclaimed material, Team Elmer’s also used:

- 1,028 tons of 22-A road gravel

- 740 tons of 6AA crushed stone

- Over 1,843 tons of hot mix asphalt

Team Elmer’s completed the first phase of work and reopened J. Maddy Parkway three days ahead of their Labor Day deadline on August 28, 2025.

| Your local Trimble Construction Division dealer |

|---|

| SITECH Michigan |

In phase two of the project, they finished the underdrain systems, catch basins, slot trench drains, retaining walls, earthwork and grading, concrete and asphalt cart and pedestrian paths, restoration, topsoil, seeding, and site fencing. Team Elmer’s started those tasks the day after Labor Day and wrapped up in November 2025.

“There was great partnership on this project,” Sanborn said. “All divisions of our company were utilized — excavation, crane and rigging, trucking, concrete, and asphalt — along with multiple subcontractors meeting required timelines.”

- Owner: Interlochen Center for the Arts, Interlochen, Michigan

- Partner Agencies: Grand Traverse County Road Commission, Grand Traverse County Soil Erosion

- Other Partners: Interlochen State Park, Consumers Energy, Merit Network, Western Telecom

- Main Contractor: Team Elmer's, Traverse City, Michigan

- Design Engineer: Jozwiak Consulting, Traverse City, Michigan

- Other Contractors: Topline Electric, Northern Concrete Pipe, Manthei Supply, Michigan Pipe & Valve, Topline Electric, Bella Concrete Construction, Kent Companies, Great Lakes Caulking, Soils & Structures, Leonardo’s Tree Service, PK Contracting, Precision Concrete Cutting, Straight Line Fence, 3rd Generation Striping & Pavement Marking, Security Sanitation, Give ‘Em A Brake Safety Photos courtesy of Team Elmer’s