Eleven OCEA Honor Awards were announced in January 2022, and the winner and two runners-up were recently announced as part of ASCE’s 2022 Convention at the Disneyland Hotel in Anaheim, California.

“These trophy winners are redesigning communities, improving mobility, and positively impacting the environment for the generations to follow,” said Dennis D. Truax, ASCE President. “Civil engineers are problem solvers, but they are also vision creators. These projects blend beauty with function and will elicit inspiration in the future workforce.”

For decades, conventional structural systems — like using a reinforced concrete core surrounded by steel framing — caused construction of high-rises to occur at a rate of around one floor per week. SpeedCore allowed construction on the Rainier Square tower to occur 43 percent faster, with up to four floors completed per week. It also shaved 10 months off what would have been a 32-month construction schedule with a conventional structural system.

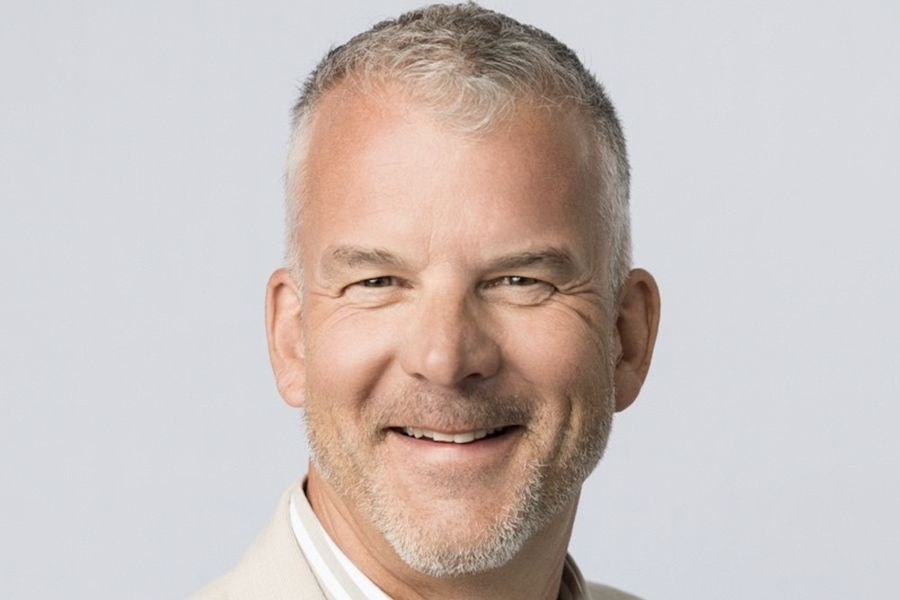

“The incentive to switch from a reinforced concrete core to some other means of bracing the building was kind of inspired by this need for speed. How do we make it go faster?” said Ron Klemencic, Chairman and CEO of Magnusson Klemencic Associates (MKA), the structural engineer on the project. “And so the idea that we conceived was, rather than building the core out of reinforced concrete with formwork and rebar and embedded plates and cast-in-place concrete, instead we built these prefabricated, modular steel panels that could be shop fabricated, trucked to the site, and then lifted into place like Lego blocks, stacked one on top of the other.”

| Your local Trimble Construction Division dealer |

|---|

| SITECH Michigan |

The SpeedCore system used more than 530 plates — each a half-inch thick, 30-to-40 feet wide, 14 feet tall, and weighing approximately six tons each. The plates were shop fabricated in connected pairs 21 to 45 inches apart, with one-inch-diameter steel tie rods to form modules ready for site installation and concrete fill. The project team was faced with a difficult decision when it came to how to obtain these plates, as the only two steel mills in the world that offered 14-foot-tall plates were in South Korea and Germany.

“Most [domestic] steel mills only roll plate up to 10 feet wide, which meant if we bought steel plates from those mills, we’d be faced with splicing all the panels together in the shop to form our 14-foot-tall panel to place in the field. So there was a kind of fork in the road as to where we're going to buy this plate material. Are we going to buy it domestically and splice it all together in the shop, or are we going to buy it offshore, imported, and at the desired width? Ultimately for Rainier Square, the choice was to buy the plates from South Korea. … The transportation costs, layered on top of the material cost from the mill was actually cheaper.”

MKA spent more than 16 years researching and testing the SpeedCore system, along with the American Institute of Steel Construction (AISC), Charles Pankow Foundation, MKA Foundation, Purdue University, Steel Institute of New York, and the University at Buffalo.

“The Rainier Square Redevelopment will inspire those who see it with its futuristic beauty, but will also protect the associated businesses and residents for years to come due to its SpeedCore system,” Truax said. “Such an innovative and visible achievement is very deserving of the OCEA honor.”

“It’s not often that a brand-new structural system comes along and has this kind of positive impact and is faster, safer, and better,” Klemencic said. “I've been practicing structural engineering for 37 years, and it's very rare, very infrequent that a whole new structural system comes along. … It's just so unique to have something so radical and so new become a reality.”

| Your local Deere & Co dealer |

|---|

| AIS Construction Equipment |

Other innovations utilized for the Rainier Square tower included bidirectional tuned liquid mass dampers and a telescopic building maintenance unit. Used for the first time in Seattle and the second in the U.S., the dampers were comprised of two rooftop 35,700-gallon water tanks that use wave action to damper and counteract wind motion. The first-of-its-kind, five-stage telescopic building maintenance unit is the world’s longest and provides nearly 160 feet of reach to access the tower’s eastern curved facade.

The project team for the Rainier Square Development included MKA as the structural engineer, Wright Runstad as the developer, NBBJ as the architect, Lease Crutcher Lewis as the general contractor, Supreme Group as the steel fabricator, and The Erection Company as the steel erector.