Facing both extreme summer heat and bitterly cold winters, asphalt streets in Jackson, Wyoming, can become brittle and cracked without frequent sealing. Searching for an environmentally friendly resurfacing option, the town’s Senior Public Works Engineer, Scott Mohror, turned to RePlay, a bio-based asphalt sealer manufactured by Missouri-based BioSpan Technologies.

Jackson’s community-wide sustainability plan includes goals to achieve net-zero emissions in its municipal operations by 2030.

“Jackson, as a town, is very environmentally friendly,” Mohror said. “As a rule, we try to do everything we can to protect the environment in the choices we make. So, the fact that this product [according to BioSpan calculations] is 88 percent ag-based, natural stuff — including 40 percent soybean oil — immediately piqued my interest.”

RePlay is a transparent liquid sealer that prevents roadway deterioration by rejuvenating the binder that keeps asphalt flexible and durable.

In August 2024, the town of Jackson partnered with Minnesota-based Bargen Incorporated — a RePlay master applicator — to apply the asphalt sealant on roughly 10 municipal streets, representing about 18,000 to 20,000 square yards. Mohror intentionally had teams apply the product to an array of asphalt types, from newer streets to much older (25- to 30-year-old roadways), to evaluate its effectiveness across use types.

| Your local Trimble Construction Division dealer |

|---|

| SITECH Michigan |

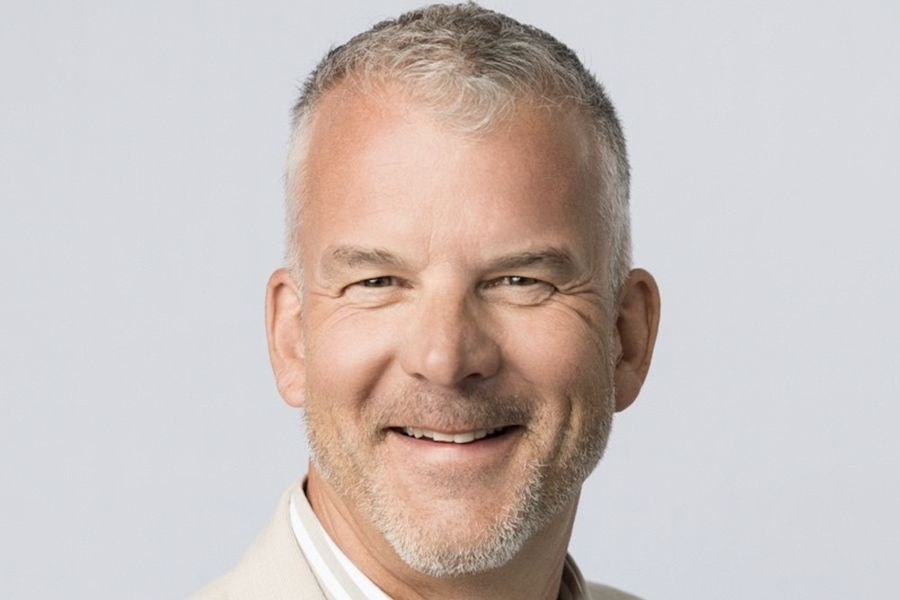

“The city wanted to apply RePlay on roadways that represented a variety of factors, including varying ages and pavement conditions, as shown by differing values of pavement condition index (PCI),” said Doug Standerwick, a Sales Manager for Bargen Inc. who helped oversee the RePlay installation in Jackson.

Bargen Inc. is an experienced RePlay applicator under Midstates Equipment and Supply Company, a BioSpan Technologies master distributor.

“Core sampling [from the 2024 Jackson trial] showed that RePlay penetrated the asphalt surface to a touch over an inch deep,” Mohror said. “The fact that this product rejuvenated the asphalt binder at an inch deep, versus just putting a petroleum-based surface treatment on, makes it beneficial to our town.”

Specifically, tests following the 2024 Jackson application found RePlay increased binder content by 5.69 percent at 1.25-inch depth on Lodgepole Lane (a 25-year-old roadway rated with a PCI of 77) and 6.19 percent at 1-inch depth on Rancher Street (a roughly three-year-old road with a PCI of 87).

| Your local Deere & Co dealer |

|---|

| AIS Construction Equipment |

The results were so promising that Jackson has already contracted with Bargen Inc. to do a second application of RePlay across 30,000 square yards of primarily older, residential roadways and municipal parking lots in summer 2025. The town has committed to investing roughly $85,000 for the second RePlay sealing project.

Produced by BioSpan Technologies for more than 25 years, RePlay is a bio-based pavement preservation solution meant to help extend roadway life. The product works by penetrating the pavement surface to restore asphalt’s essential oils, reducing brittleness, oxidation, and cracking. By rejuvenating the asphalt binder, RePlay also improves pavement flexibility so roadways can better withstand traffic stress and harsh weather exposure.

RePlay offers a “unique, carbon-negative solution” to roadway maintenance, according to BioSpan Technologies President and COO Lindsey Hermes.

“There’s nothing else like it on the market,” she said. “What sets it apart are its polymers, which lend strength and flexibility to the asphalt — leading to greater durability and longevity for those surfaces. Because of its unique chemistry, RePlay is able to penetrate further into the asphalt than other conventional [resurfacing] methods.”

| Your local Trimble Construction Division dealer |

|---|

| SITECH Michigan |

While traditional asphalt maintenance tends to leverage petroleum-based strategies, like chip sealing or asphalt emulsion products, RePlay is crop-based. That distinction makes RePlay an especially attractive alternative for cities and towns like Jackson, where a focus on environmentally friendly products is key.

“Increasingly, cities are realizing that their maintenance choices — including what we’re choosing to breathe and put back into the soil — are all really important in terms of public safety,” Hermes said.

To apply RePlay, Mohror’s public works teams first carefully cleaned the streets using town-owned street sweeping equipment. Then, Bargen Inc. team members used a Bargen truck equipped with a computer-controlled liquid spray system — akin to those used by farmers to spray their crops — to precisely spray the sealant at uniform rates on designated roads.

RePlay has a pH of 3.5 to 5.0 and should ideally be applied to dry surfaces with an optimal ambient temperature between 70 and 80 degrees Fahrenheit. BioSpan recommends using the product on asphalt roadways, parking lots, or pedestrian trails with new asphalt (at least 60 to 90 days after installation) or existing asphalt with a PCI rating above 60.

| Your local Trimble Construction Division dealer |

|---|

| SITECH Michigan |

In Jackson, Bargen’s team applied RePlay using a standard spray rate of 0.02 gallons per square yard.

“Replay doesn’t require a heavy spray rate, like many petroleum products do,” Standerwick said. “However, it’s a specialized thing. The optimal spray rate for RePlay is not one-size-fits-all.”

To determine the appropriate spray rate in a given application, Bargen teams conduct detailed surveys with city roadway teams to first determine the age, maintenance, and makeup of the asphalt, including the percentage of recycled asphalt product (RAP) in the pavement mix.

“Those kinds of variables are going to determine how we spray to ensure the best roadway benefit,” Standerwick said.

| Your local Trimble Construction Division dealer |

|---|

| SITECH Michigan |

Because it is applied relatively lightly and as a transparent liquid, RePlay cures quickly — in some conditions as little as 30 minutes — and does not require roadway lane repainting. As a result, crews can generally reopen roadways for normal use shortly after RePlay application.

“It’s a very fast process,” Mohror said. “Unlike a typical chip seal process that requires multiple passes of trucks and rollers, with RePlay, you spray it, and you just wait for it to cure. So, the carbon footprint with this process is much smaller, not only because the product is ag-based, but also because you’re cutting down on equipment gas demands and machinery exhaust, as well.”

BioSpan Technologies recommends reapplying RePlay to road surfaces every three to five years for best results. The product typically costs around $60 to $70 per gallon and has a shelf life of five years in its original, sealed container. Some municipalities opt to apply the sealant using their own spray equipment and their own dedicated road teams to help reduce labor costs involved in RePlay application, Hermes said.

Standerwick feels that if towns and municipalities committed to applying RePlay every five years, they might extend the timeline by which they would need to consider complete repavement of those roadways.

| Your local Trimble Construction Division dealer |

|---|

| SITECH Michigan |

“[Cities] would conceivably extend [roadway] life by 10 to 15 years, or possibly more, depending on the age and specifics of the asphalt — including its PCI, RAP percentage, and other variables — when initial RePlay application takes place,” Standerwick said.

“By preserving existing infrastructure, cities are able to save so much money in the long run,” Hermes added. “There's a lot of data out there to suggest that if you spend $1 today [in asphalt preservation strategies], you're going to save $8 to $10 in [reduced infrastructure replacement costs in] the future.”