“These awards are designed to set a new minimum standard of excellence for the construction industry,” said Tom Brown, AGC’s Vice President and President of Sierra Pacific West, Inc. in San Diego. “Considering what went into building these projects, that minimum standard is extremely high.”

For 41 years, the Build America Awards have recognized excellence in projects ranging across the building, highway and transportation, utility infrastructure, and federal and heavy industries. The projects are selected by a panel of judges comprised of contractors that look for projects excelling in: state-of-the-art advancement, project management, innovation in construction or use of materials, contribution to the community, client service, overcoming jobsite challenges, environmental sensitivity, and partnering excellence.

In the Rocky Mountain Construction area, the following projects were awarded with 2023 Build America Awards.

The project included four miles of two-lane freeway, on- and off-ramps, grade separated bridge crossings, 13 vehicle bridges, six pedestrian bridges, the widening of some intersections, and a new trail system. During construction, the team used an innovative paving approach that will allow the concrete to last longer and be less prone to failure.

| Your local Gomaco dealer |

|---|

| Terry Equipment |

“A lot of innovation went into the success of this project,” said Dustin Olson, President of WW Clyde. “Our team members worked long hours alongside our partners at Kiewit. It was challenging, but worth it to help improve transportation in Salt Lake City. I’m proud of what we accomplished and am grateful to the AGC for the recognition.”

There were no lost time injuries during the more than 700,000 manhours that the team worked. This section of the Mountain View Corridor will eventually become part of a 35-mile freeway that runs from I-80 in Salt Lake County to S.R. 73 in Utah County.

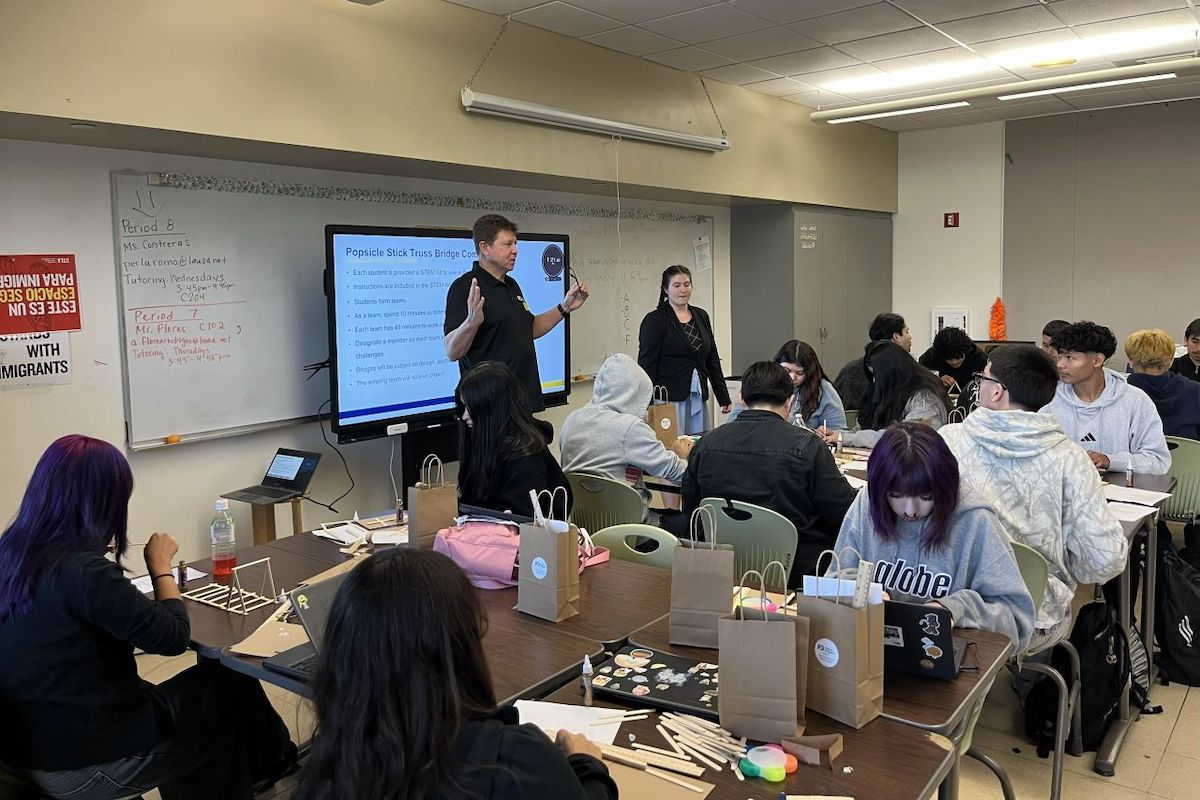

In addition to the construction work, the team also visited local elementary schools to teach students about active construction site hazards and discuss construction and equipment.

The Combs team opted to use concrete materials to enhance the road surface, rather than using asphaltic concrete (which is what the original design called for). To save time and money, a fiber mesh underlay was also added, allowing the team to pour a thinner layer of concrete.

The project also included additional improvements to make way for a new building, along with the installation of new sidewalks, driveways, curb ramps, irrigation improvements, lighting, signs, and striping. In addition, Combs Construction Company developed plans to address material shortages and to keep traffic moving through intersections during the entire project.