Within the modern construction industry, experts have increasingly turned to virtual design and construction (VDC) to strategically manage project risks. At McCarthy Building Companies, VDC is at the center of project planning, coordination, and execution to ensure the safety and quality of every build. Through advanced technology, owners, designers, and builders can collaborate seamlessly and promote safety on and off the job site.

Construction teams have consistently grappled with the challenges of translating design intent into field execution. Traditional ways of working can lead to miscommunication among team members, resulting in delays and errors on the job site.

To confront these challenges head-on and keep safety a number one priority, teams should implement digital tools to visualize, analyze, and coordinate every aspect of a project before groundbreaking. As projects become increasingly complex, VDC is the foundation of the future of construction.

One of the most impactful abilities of VDC is identifying and mitigating risks early in a project's lifecycle. Before digital tools transformed the industry, construction teams relied on 2D drawings and paper blueprints to map out designs and plan each phase of a construction project. However, these blueprints are unable to account for the changing conditions between digital design and the real-world job site.

Accounting for the spatial constraints between multiple systems is challenging, and without confidence in the design, teams might hesitate to enable prefabrication and automated robotic layout. Without the VDC process, these uncertainties can lead to increased rework in the field, contributing to workspace conflicts among trades and negatively impacting team morale.

| Your local Gomaco dealer |

|---|

| Ring Power Corporation |

| Ring Power Corporation |

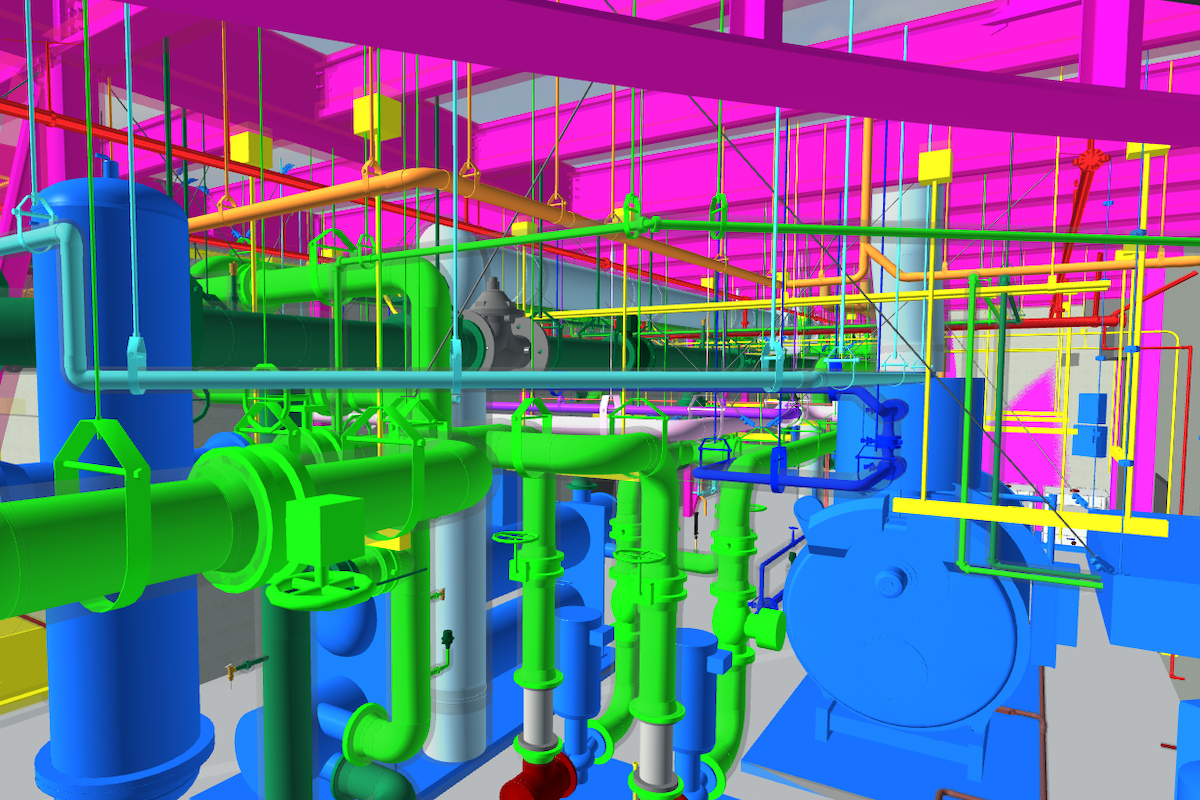

VDC uncovers and blocks early project risks during design development by bringing construction insights into the design process. 3D models are constantly evolving in scope and complexity between architects, engineers, and trade contractors. Capabilities such as clash detection allow the team to compare design-intent models with fabrication-level models to ensure precise fit and function before prefabrication takes place offsite. When existing conditions are critical to inform design, technologies such as high-definition laser scanning or 360 photo capture allow teams to compare reality with digital models ahead of onsite construction activities.

Without a true visualization of a construction project, teams often run into miscommunication, leading to unsafe site conditions. Without VDC integrated early into the construction planning process, teams may find themselves in a reactive approach to quality, schedule, and safety.

With large project teams often spread out — from office resources to boots on the ground — miscommunication can easily happen if various technologies are used without clear communication streams. In the absence of a clear visual plan before construction begins, teams may also initiate work without the right information to build from.

When VDC is leveraged most effectively and supported by a comprehensive execution plan, it allows for early integration across the project team. This alignment helps define approaches to visual planning, logistics, and model coordination, ensuring that construction means and methods are fully integrated into the planning and design process.

| Your local Komatsu America Corp dealer |

|---|

| Linder Industrial Machinery |

| Linder Industrial Machinery |

Rather than addressing risks only after they’ve appeared in the field, VDC methods and tools can spot potential risks and hazards before construction crews ever step on site. This includes proactively modeling design in a digital (BIM) enabled environment, allowing the project's stakeholders to assess constructability and better plan for prefabrication opportunities. Clash detection also ensures that building systems will fit in the spaces provided, while simultaneously reviewing clearance and serviceability zones so facilities operations staff can safely access and maintain equipment.

Prefabrication, in particular, is a key practice for improving the safety of a project and protecting the production schedule. By shifting work from the field to controlled shop environments, complex tasks such as welding or electrical work can be done on the ground, reducing the need for workers to perform tasks at dangerous heights. Automated machines can operate in a shop continuously with minimal human interaction, significantly reducing safety risks. An indoor job site also limits the field crew’s exposure to harsh, unpredictable weather conditions like rain, snow, and extreme temperatures.

Off-site construction practices significantly increase productivity, safety, and quality by reducing the pressure and stress on craftworkers on busy job sites. By shifting work to controlled conditions, teams can focus on a fully coordinated assembly supported by BIM technology.

In strengthening the connection between office and field resources, VDC promotes the productive, collaborative environment necessary among all project stakeholders with the speed and efficiency demanded in today’s fast-paced construction market.

| Your local Iowa Mold Tooling Co Inc dealer |

|---|

| Nichols Fleet Equipment |

| Nichols Fleet Equipment |

Design risks, planning errors, breakdowns in information exchange, and delays in material production can all result in breakdowns in team morale. With a shared understanding of VDC benefits — from concept through project handover — project teams can foster greater buy-in for more transparent, efficient workflows that support team member’s quality of life and promote a more integrated approach to project delivery.

As the construction industry continues to evolve, VDC has become a central, integrated practice for delivering projects digitally.

When BIM-enabled technologies were first introduced in the early 2000s, many industry leaders viewed them as more visual aids, rather than an essential function for project execution. Today, VDC is a collaborative effort connecting people, process, and technology, touching every phase of the project lifecycle. At McCarthy Building Companies, VDC has become embedded in design and construction practices to drive a modernized, digital delivery approach.

Yuhang Xu is Senior VDC Manager – Northern Pacific Region for McCarthy Building Companies, Inc.