The I-285/I-20 East Interchange in DeKalb County, Georgia, is approximately 15 miles due east from downtown Atlanta and 15 miles northeast of Hartsfield-Jackson Atlanta International Airport. It is also one of the most heavily traveled interstates in the Atlanta metropolitan area.

The I-285/I-20 East Interchange is mentioned as No. 14 on the American Transportation Research Institute’s (ATRI) 2025 list of the Top 100 Truck Bottlenecks. Each year, ATRI measures the level of truck-involved congestion at over 300 locations on the national highway system and develops a list of the top 100 bottlenecked areas, with several Atlanta-area corridors regularly cited.

These operational issues have led the Georgia Department of Transportation (GDOT) and East Interchange Builders, a joint venture of Archer Western Construction and E.R. Snell Contractor, Inc., to an active $700 million construction project to improve safety and traffic flow within the interchange. The project will construct new system-to-system ramps and auxiliary lanes, among other enhancements.

GDOT has advanced its long-term plan to address key interstate interchanges and corridors across Georgia through the Major Mobility Investment Program (MMIP), which was identified in 2016 with the goal of improving mobility in congested regions of the state.

The I-285/I-20 East Interchange was constructed in the mid-1960s. The interchange includes two large flyover bridges with low-speed cloverleaf ramps. The ramps include a sharp turn that forces traffic to slow down from the standard speed limit of 55 mph to navigate the area safely.

| Your local Wirtgen America dealer |

|---|

| Beard Equipment Co - AL |

| Tractor & Equipment |

The slowdowns result in regular backups even outside of rush hour. As of 2023, the annual average daily traffic in the I-20 corridor approached 200,000, with average truck movement on the ramps nearing 22 percent.

The interchange is between Georgia’s two largest cities — Atlanta and Augusta. The interchange also feeds into the east side of Atlanta. A continual source of peak period delays, this critical juncture in DeKalb County requires operational and geometric improvements to address an inefficient flow of traffic and safety performance.

Goals of the MMIP project include higher travel speeds, fewer conflicts due to weaving, and reduced crash frequency and severity. The redesigned interchange will provide more direct ramps with gradual curves that eliminate large speed changes and are easier and safer to drive.

The project area spans 10 miles. However, upgrading the interchange is the primary objective. The scope includes the following:

| Your local Bobcat dealer |

|---|

| Pinnacle Central Co Inc |

- Reconstructing I-285/I-20 East Interchange ramps with more direct alignments and additional lanes where warranted.

- Constructing new connecting lanes, also known as collector-distributor lanes, along westbound I-20 and an additional lane in the eastbound I-20 connecting lane road between the I-285/I-20 East Interchange and Wesley Chapel Road. The distribution will all be at one point, which is expected to optimize travel flow.

- Adding auxiliary lanes along I-20 and I-285.

- Replacing the Miller Road and Fairington Road bridges over I-20, as well as the I-20 bridge over Snapfinger Creek.

- Widening the I-285 northbound bridge over Snapfinger Road.

- Constructing new noise barriers where feasible and reasonable per the preliminary noise impact assessment.

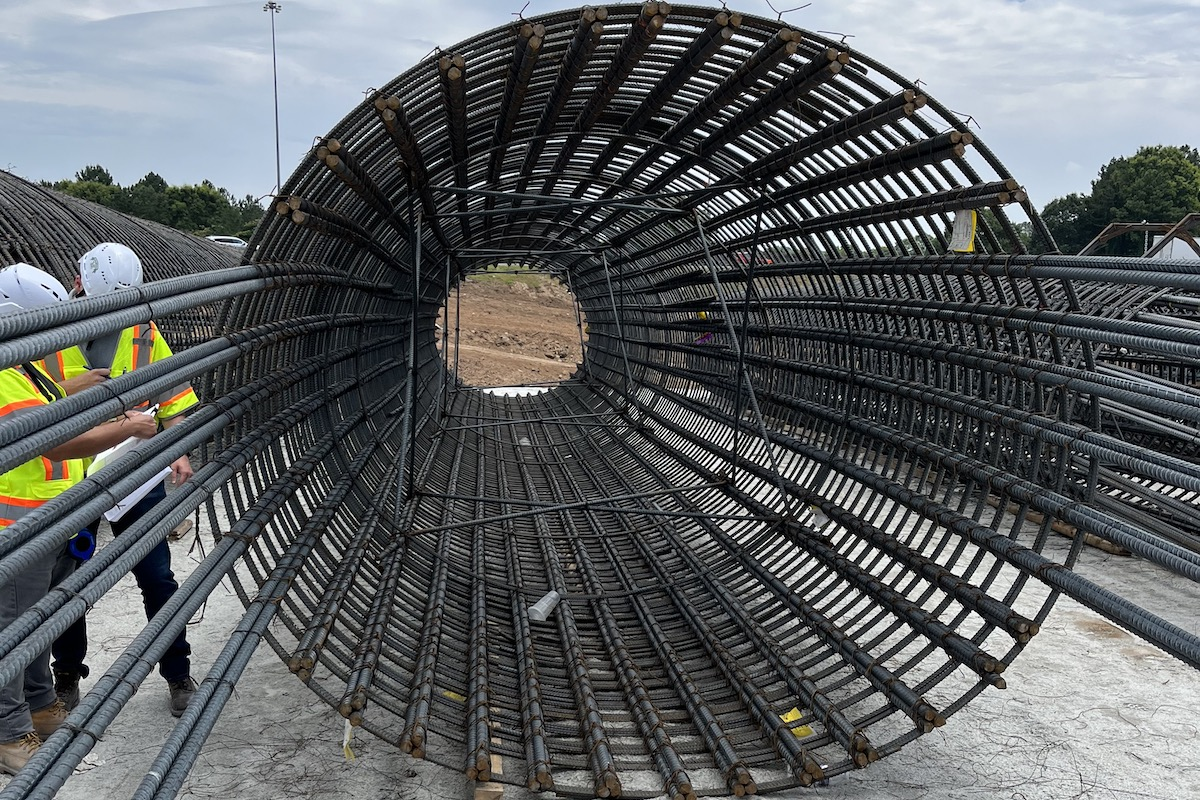

The interchange will have two new flyover bridges and three ramps. The project will widen the ramps to two lanes. A unique aspect of the design is that the flyover bridges are on drilled shafts. The shafts are 8 to 10 feet in diameter and go as deep as 130 feet.

The surrounding area is primarily residential. GDOT conducted preliminary noise impact assessments to establish where/if noise walls were needed. The team is installing 16 different noise walls that collectively cover 800,000 square feet to mitigate noise and maintain quiet in the residential neighborhoods surrounding the interchange.

Upon completion, the project will result in 18 additional lane miles. Some of those miles are east of the interchange on I-20 until Fairington Road, where many cars exit the interstate. The additions will widen the interstate from four to five lanes in some sections and from three to four lanes in others.

| Your local Iowa Mold Tooling Co Inc dealer |

|---|

| Nichols Fleet Equipment |

The widening of the Miller Road and Fairington Road bridges over I-20 is to accommodate future GDOT projects. The Snapfinger Creek bridge is a mainline bridge that crosses over the creek. The team optimized construction to reduce the environmental impact on the creek.

The extensive project employs a significant number of people. The number of craftworkers is expected to peak at 310, with a typical number near 300. There are also 100-plus subcontractors on the job at any given time.

“Maintaining staff in Atlanta, which is booming, is a challenge,” said Greg Munna, Senior Project Manager at the Walsh Group and Archer Western, who is overseeing the project. “We’re always recruiting.”

One of the best ways to maintain staff is to listen to their concerns and look out for their well-being, according to Munna.

| Your local Gomaco dealer |

|---|

| Ring Power Corporation |

“We do a deep dive in safety with our staff, so they know to make this the safest site possible,” he said.

Leadership provides the team with training to help them develop their skills. The team also meets every Tuesday for Toolbox Talks, where they discuss the biggest safety challenges they face in the field.

“The meetings help keep management in tune with what the labor force is saying and has led to changes,” Munna said.

One of those changes is the addition of hydration stations and cooling stations during the summer. The stations are stocked with electrolyte packets to keep the crew hydrated and strong.

| Your local Bomag Americas dealer |

|---|

| Linder Industrial Machinery |

A challenge that the team faces is dealing with the traveling public. The average daily traffic is elevated, and traffic around the interchange regularly moves slowly. So, shutdowns would exacerbate the problem.

The team is only allowed one lane shutdown during the day. When necessary, they follow procedures that include meetings with the DOT and issuing press alerts. Munna explains that 98 percent of lane closures are at nighttime.

There has been continuous community outreach to keep the public informed about all aspects of the project, including the installation of sound walls.

Obtaining funding to support a massive construction project can be a challenge for state DOTs. In Georgia, the state will not proceed with construction until 100 percent of the funding is secured.

| Your local Trimble Construction Division dealer |

|---|

| SITECH Mid-South |

| SITECH South |

| SITECH Tri-Rivers |

The I-285/I-20 East Interchange has a price tag of $691.7 million. To move the project forward, GDOT turned to the design-build-finance (DBF) delivery model.

“The DBF model allowed our investment group to bring in the funding, and GDOT will pay us back in increments through 2030,” Munna said.

The team is taking on multiple roles, including developer, designer, builder, and financier. Walsh Construction Group leads the consortium fronting the funds, with JP Morgan as the lead partner.

GDOT received $82 million via GARVEE bonds.

| Your local Topcon Positioning Systems Inc dealer |

|---|

| Linder Industrial Machinery |

The project is currently on budget. Munna credits open collaboration between the state and all parties for keeping the project on budget and schedule. He cites a unique type of risk sharing to lower prices.

“The state developed a risk-sharing vehicle for underground conditions,” Munna said. “There’s an owner’s allowance for whenever we run into something underground that is legitimate and unforeseen. The allowance allows us to not have to price the risk in when considering our bid.”

Factoring in the risk would drive up the bid price. East Interchange Builders would either end up with money in its pocket if there were few issues underground, or they would lose money if the underground work was costly.

“The approach is unique to GDOT and is working out well for both of us,” Munna said. “The approach has also bred partnering on the project.”

| Your local Komatsu America Corp dealer |

|---|

| Linder Industrial Machinery |

GDOT budgeted money for underground conditions, but conditions have not warranted spending all the funds.

The approach is also helping with the schedule. Construction on the project began in spring 2023 and is on schedule to conclude in fall 2026.

“The design-build method allows the schedule to be more feasibly managed, because we can work on elements while teams are designing the rest of the project,” Munna said. “It allows for fast-tracking a project.”

Another boost to the schedule is that team leaders, Archer Western and E.R. Snell, are two of the largest transportation contractors in the state of Georgia.

| Your local Wirtgen America dealer |

|---|

| Dobbs Equipment (DXC) |

“We both know how to work with GDOT,” Munna said. “This is our backyard, and we’re proud to build part of Georgia. I drive these roads with my children.”

When the project is complete, drivers will enjoy safer rides, improved traffic flow, and decreased travel times. Get ready to say goodbye to one of the nation’s worst freight bottlenecks.

- Owner: Georgia Department of Transportation

- General Contractor: East Interchange Builders, a joint venture of Archer Western Construction, Atlanta, Georgia; and E.R. Snell Contractor, Inc., Snellville, Georgia

- Designer: Infrastructure Consulting & Engineering, West Columbia, South Carolina

- Other Key Contractors: ABE Enterprises, Kennesaw, Georgia; Gosalia Concrete Constructors, Tampa, Florida; Tricor Construction, Inc., Spartanburg, South Carolina