Tommy Moore, Aftermarket Training Manager at Rokbak, forged his training philosophy on the factory floor. In fact, his journey from builder to global trainer shaped a hands-on program that delivers lower operating costs and greater machine uptime — an approach that can benefit every job site.

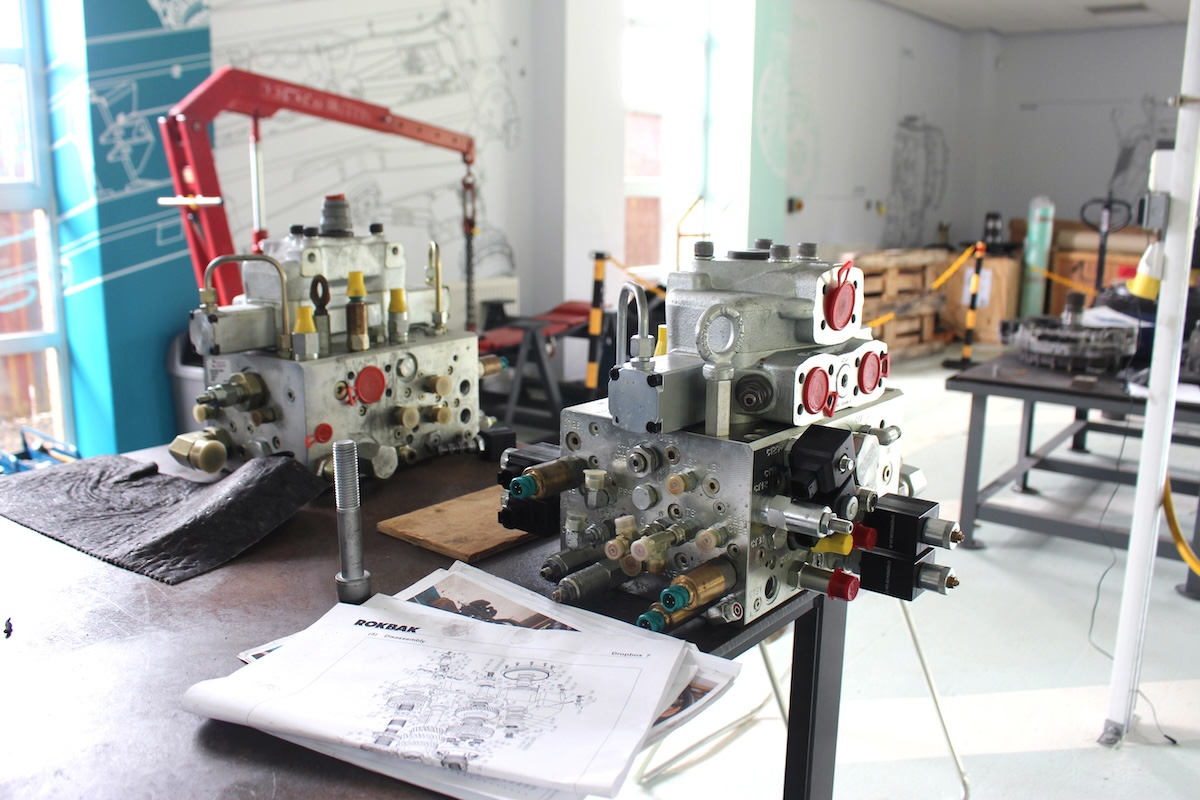

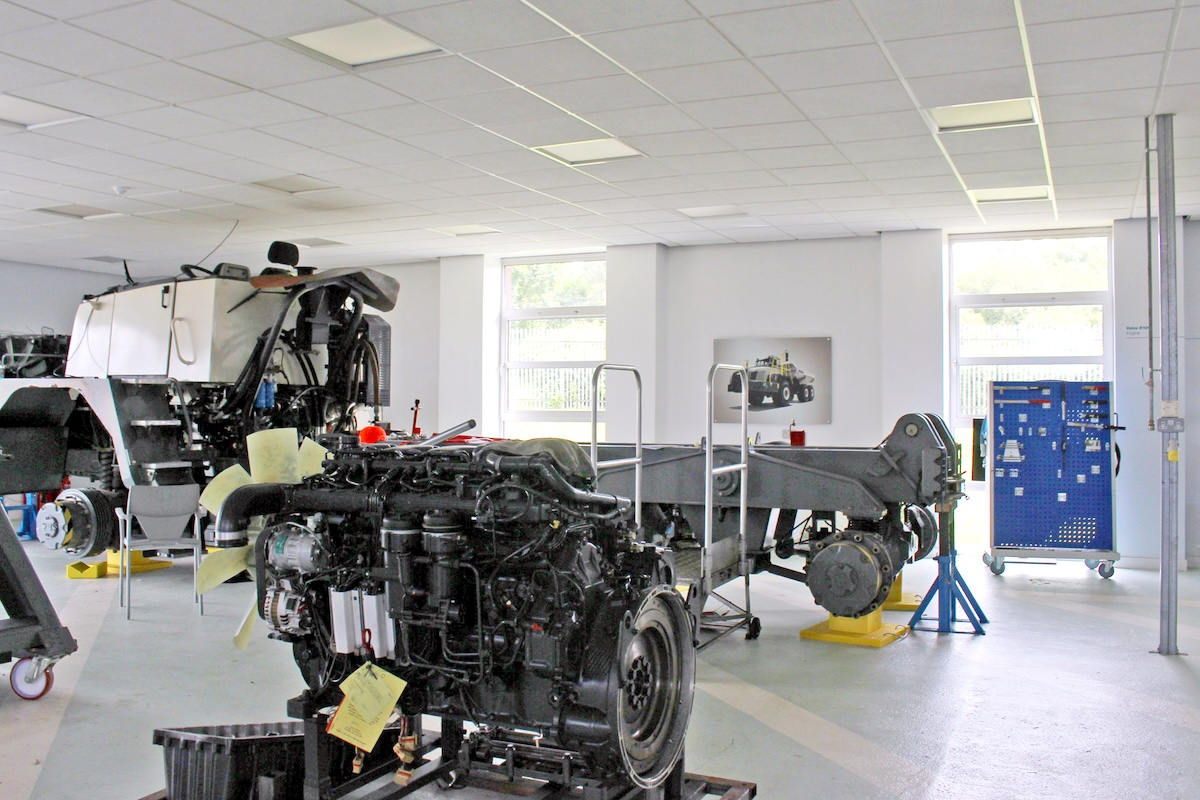

As Moore trains technicians and operators, lessons don’t happen in front of a PowerPoint slide. Moore conducts training on the workshop floor, tools in hand, surrounded by the components that keep a job site productive. It’s a hands-on, practical approach that perfectly mirrors his own journey.

Moore’s career with the Scottish articulated dump truck manufacturer didn’t begin in a classroom, but on the assembly line, physically building the haulers. That foundational experience, moving from the line to mechanical engineering — where he rewrote the standard operating procedures for building the trucks — gave him a granular understanding of every nut, bolt, and system.

Moore strives to pass on that hands-on knowledge to trainees.

“You can talk all day pointing to a picture, but it’s not the same as walking a group of technicians over to a machine, showing them the component, and demonstrating how it works right there in front of them,” he said. “When we discuss a part of the truck, we work on that part. We have a full workshop here at our headquarters in Motherwell, Scotland, where we can strip a machine down and rebuild it. That’s how people truly learn.”

| Your local Somero dealer |

|---|

| American Construction Supply |

| American Construction Supply |

A key focus of the training Moore conducts is educating operators — or teaching technicians how to educate operators — how to use the trucks to their full potential, which takes pressure off consumable parts.

“A big part of our training is showing field engineers and operators how to use the truck’s technology properly, like the retarder and gear-changing techniques,” Moore said. “If an operator isn’t using the retarder correctly, for example, they can burn through a set of brakes three times quicker than they should. By teaching them certain driving techniques, we save the customer money and keep their truck running.”

For Rokbak, four-day courses are held at the Motherwell facility, complete with a test track. Moore and his colleagues often contact participants in advance to understand any specific issues they are facing, allowing them to set up practical demonstrations to solve real-world problems.

“Being able to physically strip down an axle or transmission and have technicians get their hands on it is something we are very fortunate to be able to do,” Moore said. “We want them to leave here 100 percent comfortable with the truck.”

| Your local Trimble Construction Division dealer |

|---|

| SITECH Northwest |

| SITECH Northwest |

No matter where the sessions occur, Moore recommends following the same rule: Training must happen with equipment on-site.

“You can’t keep a group of 15 technicians interested with a presentation in a meeting room, especially when there might be some language barriers,” he said. “But get them out on the iron, doing tests, checking pressures, and diagnosing issues together — that’s a language everyone understands. They get hands-on with it.”

At the end of each course at Rokbak’s facility, attendees leave with new knowledge of the equipment and an appreciation for Scottish culture — along with Moore’s phone number as a symbol of an ongoing partnership.

“Our goal is to give them the knowledge and support they need to get the job done,” Moore said. “Their success is our success.”

| Your local Bobcat dealer |

|---|

| Pape Material Handling |

| Pape Material Handling |

No matter the machine or the topic, hands-on training leads to more confident, efficient operators, increased job site productivity, and lower operating costs.