The Kentucky Lock Addition Project, one of the most significant investments in inland navigation infrastructure in the nation, is an upgrade to the 1944-era lock on the Tennessee River at mile 22.4 in western Kentucky.

The new 110-foot-wide by 1,200-foot-long navigation lock chamber, twice the length of the current lock, is located on the landside of the existing lock. The older lock will remain in service as a secondary chamber after construction of the new chamber.

The project has been underway since the year 2000. It includes the construction of 62 new lock monoliths, the approach walls, building and bridge construction, site development, and utilities development.

The Tennessee Valley Authority has owned the current lock and the adjacent hydropower facility since 1962. The Nashville District of the U.S. Army Corps of Engineers (USACE) is responsible for operating and maintaining the navigation facility, as well as overseeing its major construction projects.

Primary contractor Thalle Construction Company — a subsidiary of Tully Group — out of Hillsborough, North Carolina, was awarded the $380 million base contract in September 2021. In March 2022, eight additional contract options were awarded. The contract is now scheduled for completion in August 2027.

| Your local Takeuchi Mfg Ltd dealer |

|---|

| Brandeis Machinery |

“Their team is delivering the new lock chamber’s structural build-out and will install the 100-foot downstream miter gates,” said James Shibata, the Kentucky Lock Addition Project Manager from USACE.

Over the project's lifespan, USACE has received funding through various means, including the president's annual budget appropriations, annual congressional funding allocations (also referred to as funding pots), supplemental funding (from the American Recovery and Reinvestment Act and the Bipartisan Infrastructure Law), and the Inland Waterways Trust Fund (IWTF). The Construction General Account and the IWTF share the cost. The cost share ratio has changed over the years, as prescribed in the Water Resources Development Act.

“When funding is portioned out over time, it extends the construction schedule and increases overall costs,” Shibata said.

This critical lock serves as the key access point to the Cumberland and Tennessee River basins, as well as to the Mississippi and Ohio rivers.

| Your local Komatsu America Corp dealer |

|---|

| Brandeis Machinery |

By increasing the lock capacity, the new chamber will be able to accommodate 15 barge-tows, thus eliminating the lock’s well-known delays that left barges previously waiting hours, and sometimes days, to get through.

“The larger lock chamber construction is the solution to the riverway traffic congestion issues at the facility, which is too small to handle today’s inland waterway traffic efficiently. ... On average, vessels experience 10-hour delays or longer — some of the longest in the nation,” Shibata said. “With the new lock, most commercial tows will pass through in a single lockage.”

“When complete, the project will deliver long-term benefits like significantly reduced wait times, improved commerce flow along the river, and regional economic stimulus,” he added.

Additionally, USACE is working closely with inland navigation industry partners to ensure that the remaining operational features of the lock support the safe, efficient, and reliable movement of vessels.

| Your local Deere & Co dealer |

|---|

| West Side Tractor Sales Co |

“Our collaboration provides the final lock design that meets the real-world needs of the operators who depend on this critical infrastructure,” Shibata said.

According to Shibata, the project delivery team is utilizing multiple innovative technologies to enhance efficiency, reduce costs, and minimize disruptions to navigation.

For example, incorporating Building Information Modeling (BIM) helps identify potential design conflicts early before construction begins. Identifying conflicts early allows USACE to adjust during the design phase, where changes in the field can be more expensive.

“The contractor was also utilizing large, precast concrete segments for in-the-wet downstream cofferdam construction, which enabled crews to work in the river without requiring lengthy lock chamber closures, thereby further avoiding delays for the navigation industry,” Shibata said.

| Your local Wirtgen America dealer |

|---|

| Brandeis Machinery |

The project has three remaining phases before completion. The first, now 50 percent complete, is the ongoing construction of the downstream monoliths, which form the structural foundation of the new lock chamber.

The team of contractors — including Delta Demo Group, Innovative Cutting Incorporated, Heede Southeast, Inc., and others — are currently focused on constructing 52 downstream lock monoliths.

These monoliths will form the new lock chamber’s structure consisting of approximately 375,000 cubic yards of concrete — the same amount of concrete contained in just over 10 Washington Monuments.

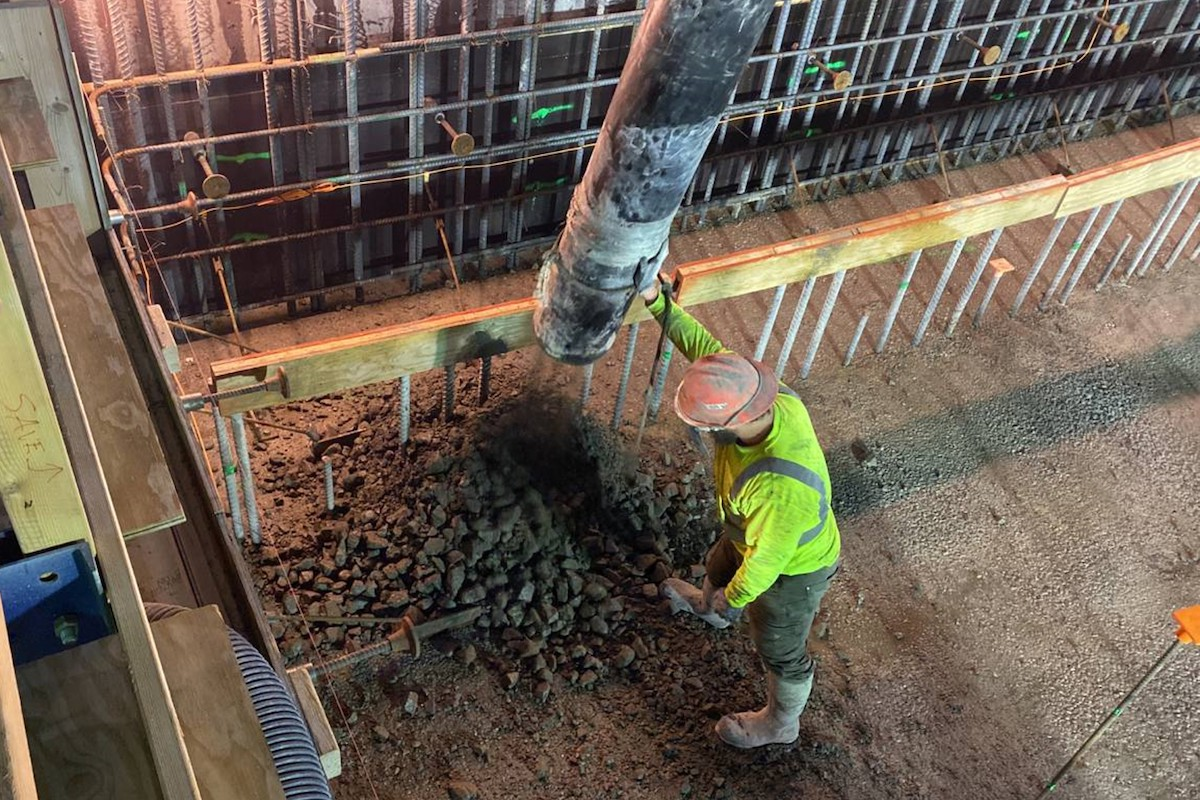

Thalle Construction is producing the concrete for the downstream monolith project using regional materials at an onsite batch plant, as well as transporting it for placement via conveyor systems and tower-crane placers.

| Your local Sennebogen LLC dealer |

|---|

| Brandeis Machinery |

At 110 feet high, 50 feet long, and 75 feet at the base, narrowing to 25 feet at top, each monolith averages 11,000 cubic yards of heavy reinforced concrete.

The contractors will perform work across 1,235 distinct lifts, each requiring the installation of formwork and the placement of rebar.

The contractors for the two remaining contracts are to be determined, with a completion date estimated between 2029 and 2031.

The project involves several specialized pieces of equipment.

| Your local Case Construction Equipment Inc dealer |

|---|

| Burris Equipment |

A heavy-lift catamaran barge, equipped with strand jacks, placed large, precast concrete segments to form the downstream-segmental cofferdam, allowing for precise in-the-wet construction while minimizing navigation closures.

Additionally, a tower crane placer and conveyor system are delivering concrete to ensure the efficient and continuous placement of the 375,000 cubic yards of concrete needed to build the new lock chamber.

“The USACE and its contractor selected these pieces of specialized equipment to maximize efficiency, ensure workers' safety, and minimize impacts on river traffic during construction,” Shibata said.

The Kentucky Lock Addition Project will generate an estimated $114.3 million in annual economic benefits by reducing delays and improving efficiency along a vital stretch of the Tennessee River.

| Your local LeeBoy dealer |

|---|

| Brandeis Machinery |

These savings come primarily from faster lockages for commercial tows, which lowers transportation costs, reduces fuel consumption, and creates fewer emissions.

“This is a long-term investment in modernizing navigation infrastructure, and its cost reflects both the scale and complexity of the work,” Shibata said. “The fully funded cost estimate is currently undergoing an enterprise-level technical review, and a re-certified estimate is expected around September 2025.”

Additionally, the project helps sustain regional jobs tied to inland navigation and industry, supporting both the local economy and the inland waterways system’s broader economic engine.

Next up is the award and construction of the approach wall contract, and the final phase is the lock operational contract. Both are critical to delivering a modern, fully functional lock that will sustain navigation reliability for decades to come.

| Your local New Holland dealer |

|---|

| Burris Equipment |

The project delivery date is currently under review as the design nears completion and the project team reevaluates risks.

The downstream lock monoliths contract, the largest current construction phase, is expected to be completed by fall of 2027.

Opening the new lock requires awarding and completing the remaining approach wall contract and the lock operational systems contract. USACE expects to have a fully updated project schedule and cost estimate finalized and certified later this year. Once complete, they will share the revised cost and estimated completion date with stakeholders.

According to USACE, due to the project’s national significance and the critical role the Kentucky Lock plays in inland navigation, they have assigned the Inland Navigation Design Center (INDC) as the official designer of record and applied engineering resources to the final design for the remaining work features.

| Your local Atlas Copco CMT USA dealer |

|---|

| Brandeis Machinery |

The INDC brought together USACE’s top design professionals and leveraged the enterprise’s best practices to complete the design for the new lock chamber.

Additionally, project delivery responsibilities have transferred from the Nashville District to the Pittsburgh District to further support the project’s execution and success. The transition matches the project's complexity.

“With the recent completion of J. P. Murtha Locks and Dam, and its proximity to INDC, Pittsburgh is ideally suited to bring its project management and scheduling expertise to the project,” Shibata said. “The Nashville District laid a strong foundation and transitioning the project and both districts are leveraging their engineering expertise to the next phase of construction at Kentucky Lock.”

“While large-scale construction projects come with challenges, the USACE remains committed to delivering a high-value, long-lasting solution for the navigation industry and the region,” Shibata added. “We look forward to advancing the project with our stakeholders and our industry partners as we modernize this vital piece of the nation's waterway system.”

| Your local Bobcat dealer |

|---|

| O'Leary's Contractors Equipment & Supply |

- Owner: U.S. Army Corps of Engineers

- General Contractor: Thalle Construction, Hillsborough, North Carolina

- Designer: Inland Navigation Design Center, Rock Island, Illinois

- Subcontractors: Bacon Farmer Workman Engineering & Testing, Inc. (surveying); Bloomsdale Excavating Company, Inc. (earthwork); Bridge Diagnostics, Inc. (specialties); Coastal Drilling East (specialties); Collier Electrical Service, Inc. (electric special systems); Forefront Robotic Services, Inc., DBA Delta Demo Group (concrete); Heath Buildings (pre-engineered buildings); Heede Southeast, Inc. (cranes); Heeter Geotechnical Construction, LLC (earthwork); Innovative Cutting Incorporated (specialties); K&N Steel (reinforcing steel); KESCO (specialties); Ludwig Drilling (specialties); S&ME (other); Select Concrete (concrete); Select Concrete Services (concrete); Terra Testing, Inc. (specialties); Travis Construction Company (pre-engineered buildings)