“The old bridge exceeded its life expectancy,” says Lauren Giarmo, Construction Engineer for the Florida Department of Transportation (FDOT). “Due to the wider and heavier loads for the space industry, we needed a new bridge.”

The eastbound structure was designed and built 11 feet wider than the westbound bridge to accommodate heavy and oversized loads going into the spaceport, and to carry four lanes of traffic while the westbound bridge is constructed.

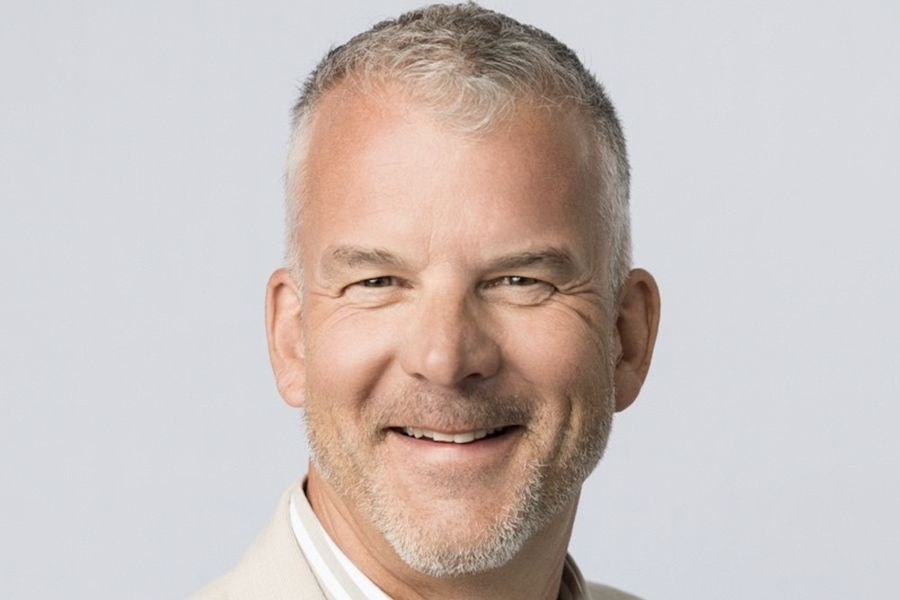

“The new bridges are more modern and have been designed and constructed with the latest standards and specifications,” says Jim Lynch, Project Manager for WSP USA of Orlando, Florida, performing construction engineering and inspection for FDOT. WSP is an engineering and environment firm.

Engineering firm Volkert of Maitland, Florida, led the preliminary engineering phase and final design phase of the project, and it did so on an accelerated schedule to get to construction as quickly as possible.

| Your local Trimble Construction Division dealer |

|---|

| SITECH Michigan |

The new bridges have 3 percent approach grades, leading to the main channel span, rather than the traditional 5 percent to 7 percent grade, to transport the heavy spacecraft flight hardware more easily across the bridge to Kennedy Space Center. The 3-mile-long causeway is federal property. NASA had maintained the bascule bridges. Going forward, FDOT will maintain the new structures.

While FDOT led and managed the design and construction phases of the new bridges, NASA remained involved. The State of Florida received a $90 million Infrastructure for Rebuilding America Grant (INFRA) from the U.S. Department of Transportation for this project.

The area has seen a significant increase in the number of launches this year. As of October, 59 rockets had taken off from the Space Coast in 2023. The aerospace industry supports more than 150,000 local jobs. “Oversized loads are coming over the new bridge every week,” Lynch says. “The frequency of launches has increased dramatically.”

During some critical launches, construction temporarily shuts down to allow physical security operations to support public attendance and local viewing. During an October 2023 Falcon Heavy launch, the team lost two days, since bad weather delayed the launch. Additionally, some excavation is prohibited during launches to ensure critical communication lines are not cut.

Despite those challenges, the first bridge opened 125 days ahead of the original schedule in June 2023.

“I am proud that they were able to finish the first bridge quickly,” Lynch says. “It was a real joint effort to have a project be this far ahead. Everybody is working together as a team to remove any obstacle to progress.”

Giarmo agreed that there has been “great partnering” on the project.

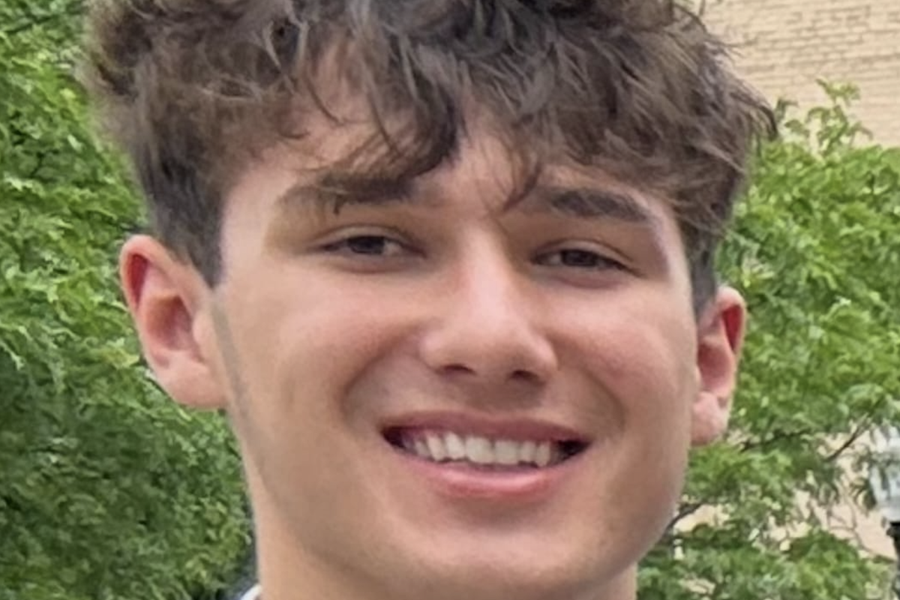

“We were very excited about it,” says Tyler Satterfield, Project Manager for Orion. “The whole team worked very hard to maintain schedules to reach this milestone.”

Giarmo indicates FDOT was happy to provide the incentive, because the new structures provide a safer bridge to the spaceport.

Orion sequenced construction so that crews were working on columns and pile caps while setting beams and pouring bridge deck at the same time in a different portion of the bridge.

“We were able to get creative in how we sequenced the work in a way that was beneficial to us,” says Edson Corredor, Assistant Project Manager with Orion. “There were a lot of good ideas implemented, which led to a nonlinear but successful project schedule execution.”

For instance, the team kept portions of the old bridge intact and used it to load and unload materials from the land to the barges.

“From January 2023 until Phase 1 eastbound bridge opening, there was a big push,” Satterfield adds. “The team did a great job of getting to the finish line.”

The work primarily takes place from multiple barges in the river. In Phase 2 construction, there are eight piers total on land on the east and west sides.

“The biggest challenge when working with cranes on barges is the daily preparation and coordination of barge moves to execute the work efficiently,” Satterfield says. “Our project management team does an impressive job developing schedules, work plans, and lift plans to overcome this challenge.”

Each new 4,025 foot, 26 span bridge has 25 hammerhead piers, which are supported by prestressed, hollow 30-inch square concrete piles.

“All of the concrete elements, except the bridge deck, are considered mass concrete, which require temperature control and monitoring to prevent cracking,” Lynch says.

The girders are Florida I beams, 78 inches and 96 inches deep. The crane height was limited to 150 feet above ground, per the Federal Aviation Administration due to proximity to a nearby airport.

“The project’s environment is spectacular,” reports Lynch. Team members have seen dolphin feeding on bait fish and jumping out of the water during pile driving. “We have also seen manatees, alligators, and water birds of all kinds. The entire project is located in the 140,000-acre Merritt Island National Wildlife Refuge.”

Throughout construction, crews had to ensure no turbid water or erosion was released to the pristine water. “The contractor has done a good job of keeping their erosion control devices in good working condition,” Lynch says.

Once traffic shifted to the new eastbound bridge, the old bridge was taken out of service. Satterfield stated that removing the existing bridge has its challenges, but it is very rewarding to see progress as the structure is removed.

Orion crews cut the superstructure spans into sections and lifted them off the bridges with cranes. They then placed them on barges or trailers and transported to a processing location onsite. Nothing can be dropped into the water. WSP has hired divers to ensure nothing has fallen into the river.

There are four bascule foundations. Orion Marine crews have driven sheet pile around those creating a coffer cell, to contain the work. The team will pump out the water, start chipping the concrete away, and pick up the debris with a clamshell bucket. They will then pull out the old H-piles from the foundation.

“Removing the bascule pier is by no means easy,” Lynch says. “It’s one big block of concrete, and it has to be removed down to the mud line.”

Orion has kept ahead of schedule while maintaining safety. Crews have worked more than 250,000 manhours without a recordable incident.

FDOT anticipates the second bridge will open in early 2026. If Orion Marine finishes ahead of schedule in March 2025, 336 days early, the company stands to earn an additional $2 million in early completion incentives.

“They are on track to meet this,” Lynch says. “At present, they are 23 percent ahead of schedule. It is quite impressive.”