With a focus on continuous improvement, the expansion included a re-layout of the production area to increase efficiency of door and frame units produced in Walker.

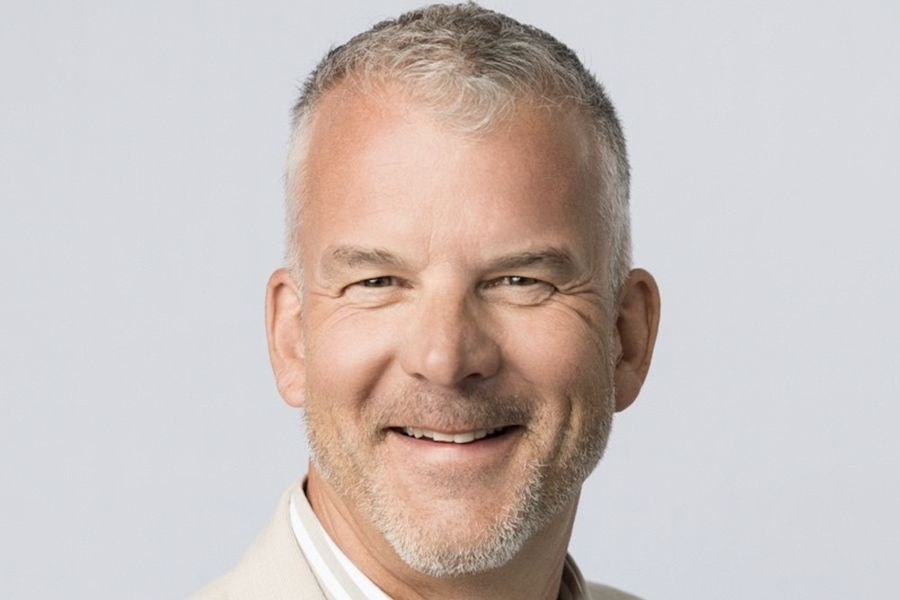

“During the expansion, we were able to facilitate a number of improvements to the flow of material and add capacity to support Tubelite's future growth,” said Jason Meredith, Tubelite's Walker Operations Manager. "A one-piece flow line for our stock and modified door leafs, allows us to enhance overall quality for our customers, while improving ergonomics and other safety items for our employees, and further supporting Tubelite's 'Dependable' brand promise."

Complementing Tubelite's Walker facility expansion in 2016, which added an engineering test lab, a fabrication training area and larger space for extrusion racking, the current operating space now encompasses a total of 180,000 square feet. The facility in Reed City, Michigan, continues to house the company's aluminum extrusion operation and its Dallas location provides additional fabrication, warehouse and shipping operations.