It can be overwhelming when you think about how much technology is on a job site today. From connected machinery and geographic information system (GIS) platforms to lidar-equipped devices and aerial data capture, teams today are working with more tools and data than ever before.

Even with all this gear, there’s not an easy way to share information between technologies or with users who aren’t trained in the specific systems.

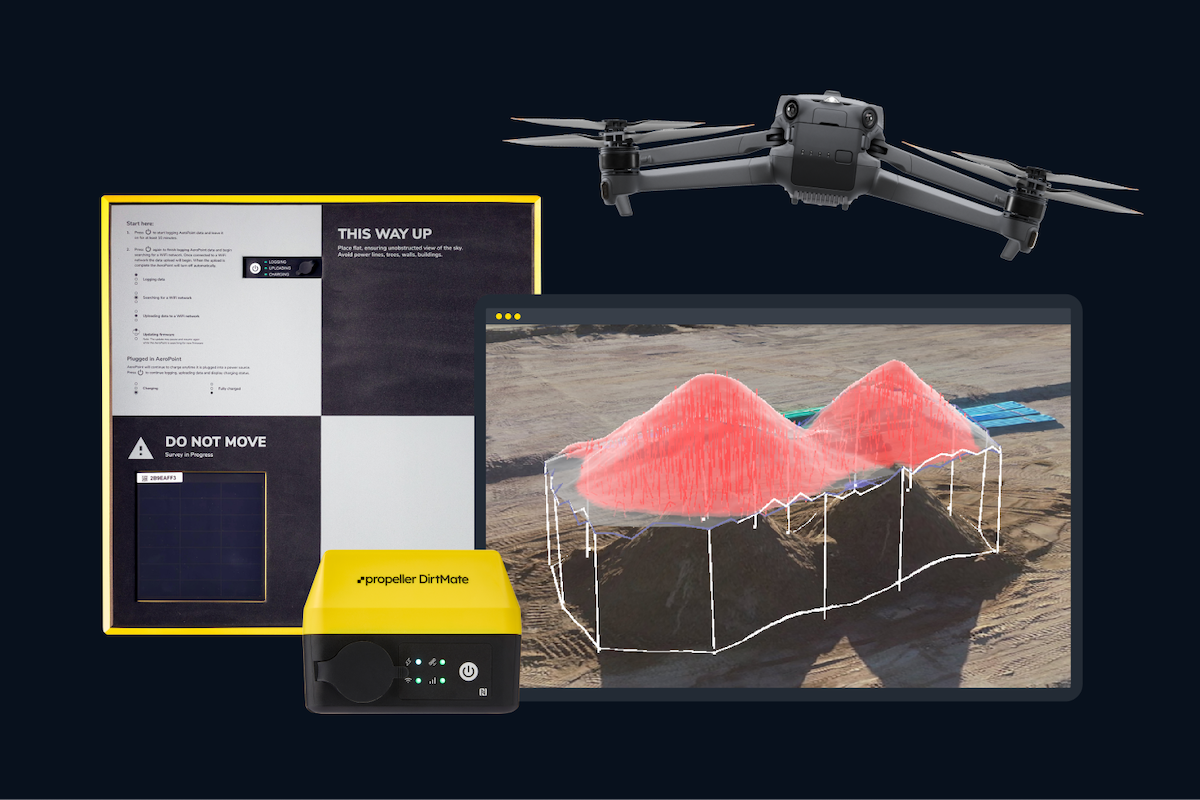

The project team’s toolbelt is ever-evolving, and there has been a growing appetite for integration between all the available technology (a budding market expected to reach $1.5 billion by 2030, according to one estimate). The need and demand for new surface data has long exceeded the speed and capacity of traditional surveying methods to deliver it. The good news is that drones have solved this for most work sites.

But now there’s a new problem — siloed data. All these tools require their own systems. And unless you’re trained on each platform, that data might as well be buried. Which begs the question: What good is fast, high-volume data capture if you can’t easily action it?

Everyone's working hard, but not always from the same playbook. You see it in everyday frustrations — three haul trucks bottlenecked at a load site, a foreman in need of a grade check, an engineer sitting on updated designs that the field needs to stay within spec. Each instance seems small, but they add up fast.

| Your local Trimble Construction Division dealer |

|---|

| SITECH Northwest |

| SITECH Northwest |

For instance, construction teams lose many hours a week on non-essential tasks like chasing down information or fixing errors. That lost time adds to labor costs. Studies show that large proportions of rework result from poor data and miscommunication; those costs are avoidable.

The results:

- You lose time — Little delays compound, pushing schedules and increasing costs.

- You lose confidence — When data is fragmented, people hesitate. Operators fear rework, foremen play it safe, and engineers spend too much time triple checking.

- You lose alignment and morale — If everyone has a different version of the truth, small issues fester into big problems like clashes, rework, or budget surprises.

So, what’s the fix? Put it all on a map, then have everyone follow the map.

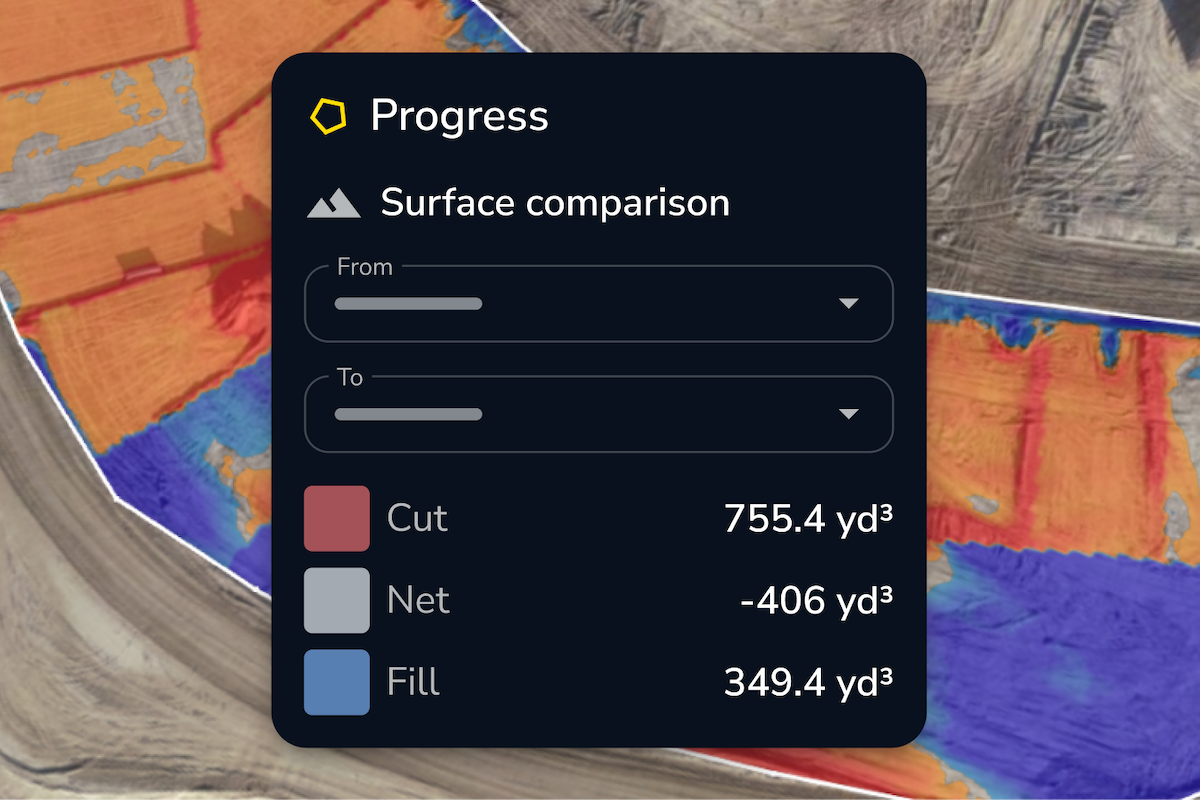

Project teams are already building this shared map, often by making their existing tools work better together. Survey updates, machine activity, design changes, field notes — all in one place, in real time. No more emailing huge PDFs or wondering if you have the latest file. Systems that were previously siloed within different teams converge to deliver more insights to more people.

| Your local Bobcat dealer |

|---|

| Pape Material Handling |

| Pape Material Handling |

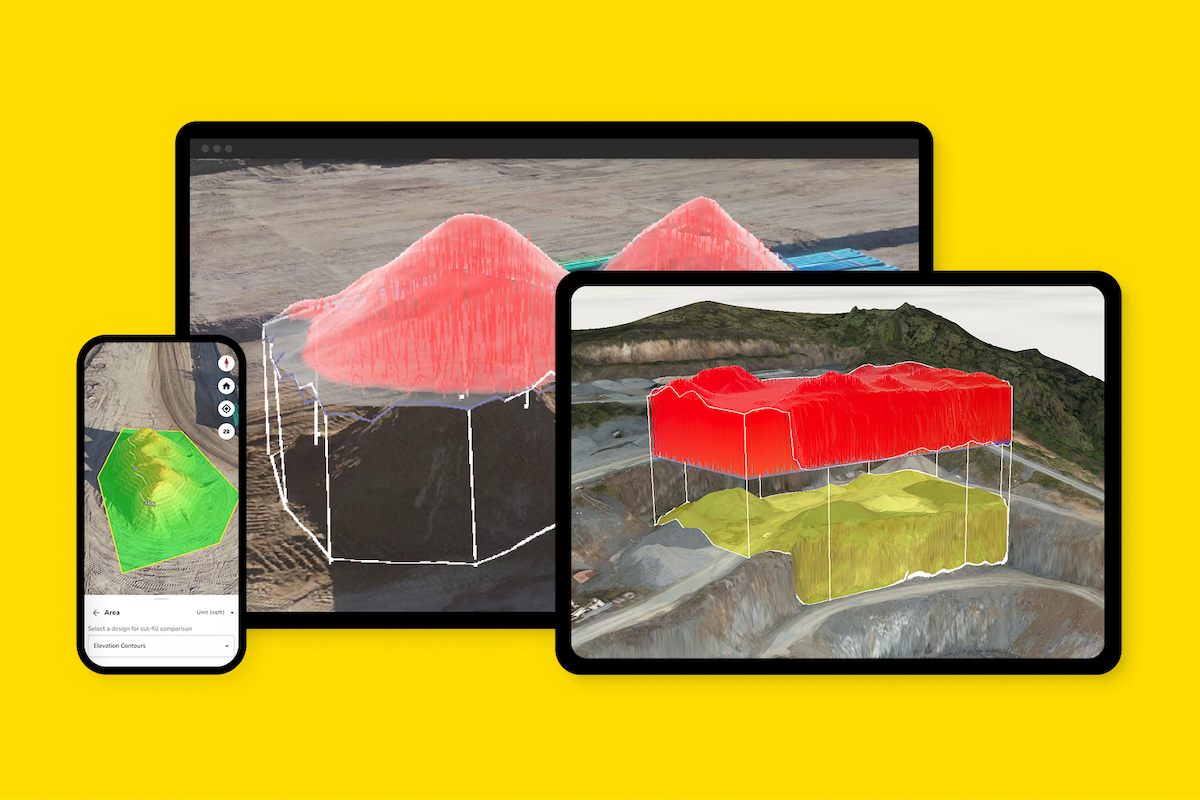

While surveyors are often ground zero for capturing survey-grade data, they represent a small percentage of users. The main users (think project managers, engineers, foremen) utilize integrated platforms as a self-serve tool, turning that single source of truth into daily decisions for the entire team.

As soon as you put all the complex documentation that construction’s been dealing with for decades into a visual form, it’s a lot easier to follow. It frees up the surveyor to spend more time surveying (versus handling analysis requests). It gives supervisors daily visibility, which creates accountability. And project managers can operate from one source of truth.

A connected map isn’t just digital; it’s dynamic. It moves with the work. Field teams see what the office sees. Operators know where they are and what to do. Engineers can track progress remotely. Everyone is literally on the same page (or map). It doesn’t matter how you're capturing data, as long as it all connects in a shared view.

Connecting workflows isn’t always glamorous. It's easier to get excited about new equipment than integrating software. Plus, there’s no one-size-fits-all solution; you have to figure out what works for your jobs.

| Your local Metso Minerals Industries Inc dealer |

|---|

| PacWest Machinery |

| Westate Machinery Co |

| PacWest Machinery |

| Westate Machinery Co |

Other issues get in the way, too: perceived complexity, upfront cost (even with long-term ROI), resistance to change, skills gaps, no internal champion for the change. But the crews that do figure it out are the ones catching design conflicts early, avoiding rework, and hitting deadlines with less chaos. It’s not about having the most technology; it’s about making your technologies talk to each other.

If you look around the industry, you’ll see a shift is already happening. The gap is widening between teams that are guessing and those that know for sure. The resources to build a single source of truth on your work site aren't abstract future concepts; they’re practical, accessible tools being used right now.

For those leveraging this kind of technology, one theme you hear consistently is the importance of getting buy-in from the field first. This is huge. If a map or a workflow only makes sense in the office, it will fail on the work site. When you pull in your foremen and operators early, you’re not just asking for their approval. You’re building a solution that works for everyone. Their feedback is gold, and it’s the key to unlocking real efficiency.

But a connected map isn't just about efficiency; it’s about building trust, too. It’s giving everyone confidence that the data they’re seeing is real, current, and accurate. No more making calls based on a guess or an outdated file. When people trust the data, they make better, faster decisions; collaborate more effectively; and make fewer mistakes.

| Your local Somero dealer |

|---|

| American Construction Supply |

| American Construction Supply |

Project teams aren’t just chasing new technology because they can. They’re solving real problems with the tools that fit best. They build maps that match the real world because that shared, trusted understanding keeps work moving smoothly and safely. It fosters a proactive culture.

And that’s the future of the job site: one map, one truth, everyone moving together with clarity and confidence. It’s about technology bringing people and information together so we can all build a little smarter.

Rory San Miguel is CEO/Founder of Propeller. He lives and breathes earthworks technology to help crews work smarter and more efficiently by turning data into decisions that make a difference onsite.